Future Trends in Procurement Automation: The Rise of Predictive Intelligence

Transforming Procurement from Cost Center to Strategic Advantage Through Predictive Intelligence

Executive Summary

Procurement automation has undergone a remarkable transformation over the past decade. What began as simple digitization of purchase orders has evolved into sophisticated, AI-driven systems capable of anticipating needs before they arise. As enterprises grapple with increasingly complex supply chains, volatile markets, and mounting pressure to optimize every dollar spent, the limitations of traditional automation have become starkly apparent. The next frontier isn't just about doing things faster—it's about doing them smarter, with foresight rather than hindsight.

This evolution toward predictive procurement automation represents a fundamental shift in how organizations approach spend management. Rather than merely processing transactions more efficiently, modern systems can forecast supplier behavior, identify emerging risks, and recommend strategic actions before problems materialize. Solutions like Hyperbots' AI Copilot are already pioneering this frontier, demonstrating how predictive intelligence transforms procurement from a tactical function into a strategic advantage. This article explores the trends reshaping procurement automation, the business imperatives driving adoption, and the practical pathways organizations can take to harness predictive capabilities.

The Evolution of Procurement Automation

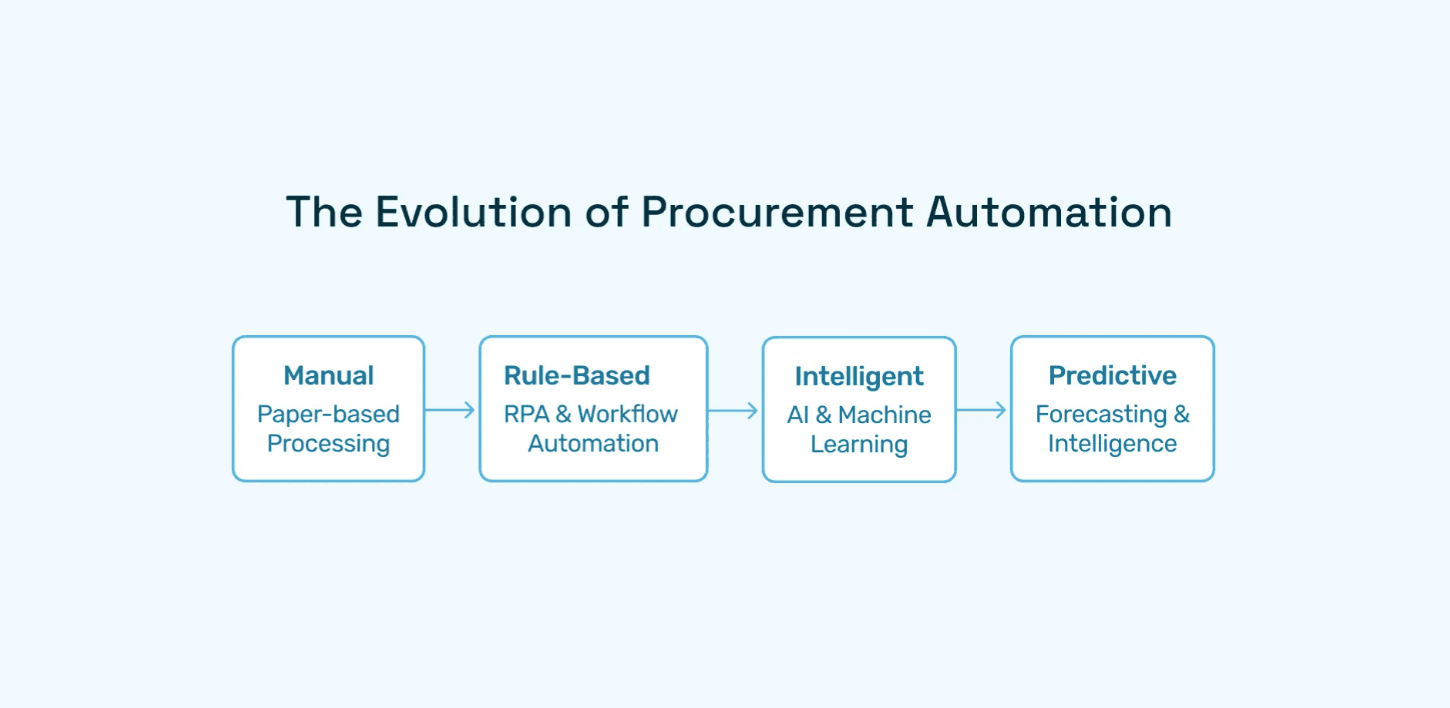

Procurement automation's journey mirrors the broader trajectory of enterprise technology—from rule-based efficiency to intelligent, adaptive systems. Early automation focused on eliminating paper-based processes, introducing optical character recognition to digitize invoices and purchase orders. While this represented significant progress, these systems remained fundamentally reactive, dependent on human intervention to handle exceptions or make judgment calls.

The next wave brought robotic process automation, which could execute predefined workflows with impressive speed and consistency. RPA excelled at repetitive tasks—matching purchase orders to invoices, checking budget availability, routing approvals—but it couldn't adapt to new scenarios or learn from experience. Each exception still required human resolution, and the system remained blind to patterns that might inform better decisions.

Manual → Rule-based (RPA) → Intelligent (AI/ML) → Predictive

From Reactive to Predictive Procurement

The introduction of artificial intelligence marked a watershed moment. Rather than simply automating existing processes, AI-enabled systems began to understand context, recognize patterns, and improve over time. Machine learning algorithms could identify which purchase requests were likely to face delays, which suppliers consistently delivered on time, and which spending patterns deviated from historical norms.

This shift from reactive to predictive represents more than technological advancement—it reflects a fundamental reimagining of procurement's role. Predictive systems don't just respond to requisitions; they anticipate needs based on consumption patterns, seasonality, and business cycles. They don't just flag budget overruns; they forecast spending trajectories and alert finance teams to potential issues weeks in advance.

Why Traditional Automation Isn't Enough Anymore

Today's business environment demands more than efficiency gains. Supply chain disruptions, regulatory complexity, and competitive pressure require procurement systems that can think ahead. Traditional automation creates bottlenecks when faced with ambiguous scenarios, generating exception queues that overwhelm procurement teams. As transaction volumes grow and supplier networks become more complex, rule-based systems scale poorly, requiring constant maintenance and rule adjustments.

The data richness available to modern enterprises—spanning historical transactions, market intelligence, supplier performance metrics, and external signals—remains largely untapped by conventional automation. Predictive procurement automation bridges this gap, transforming data into actionable foresight.

What is Predictive Procurement Automation?

Predictive procurement automation leverages machine learning and advanced analytics to forecast procurement needs, optimize supplier relationships, and proactively manage risks. Unlike traditional automation, which executes predetermined rules, predictive systems learn from historical patterns and adapt their behavior based on outcomes.

At its core, predictive procurement combines several technological capabilities. Machine learning algorithms analyze vast datasets to identify patterns invisible to human observers—subtle correlations between supplier lead times and market conditions, relationships between requisition timing and approval delays, or hidden indicators of supplier financial stress. Natural language processing enables systems to understand unstructured data in emails, contracts, and supplier communications, extracting insights that inform predictions.

Core Capabilities of Predictive Systems

Pattern recognition forms the foundation of predictive procurement. By analyzing years of transaction history, these systems identify seasonal demand fluctuations, recognize supplier reliability patterns, and detect anomalies that might signal fraud or compliance issues. This goes beyond simple statistical analysis—advanced algorithms can distinguish meaningful patterns from random noise, continuously refining their models as new data becomes available.

Spend forecasting represents another critical capability. Rather than extrapolating from past budgets, predictive systems consider multiple variables: business growth trajectories, seasonal patterns, market price trends, and even external factors like economic indicators or industry-specific events. This enables finance teams to anticipate cash flow requirements with unprecedented accuracy, optimizing working capital management.

Risk anticipation transforms how organizations manage supplier relationships. Predictive models can assess supplier financial health by analyzing payment patterns, delivery consistency, and external risk factors. When a supplier shows early warning signs of distress, the system can alert procurement teams to develop contingency plans before disruptions occur.

Benefits: From Speed to Strategic Foresight

The advantages of predictive procurement extend far beyond operational efficiency. While faster processing and reduced manual intervention matter, the strategic benefits prove even more compelling. Predictive systems shift procurement from a reactive cost center to a proactive value creator.

Enhanced decision quality emerges from having relevant insights at the point of decision. When creating a purchase order, predictive systems can suggest optimal order quantities based on demand forecasts, recommend alternative suppliers if the preferred vendor shows risk signals, and flag potential compliance issues before commitments are made.

Working capital optimization becomes achievable when organizations can accurately forecast procurement spending weeks or months in advance. Finance teams gain the visibility needed to optimize payment timing, negotiate better terms, and ensure adequate liquidity without maintaining excessive cash reserves.

Risk mitigation moves from reactive problem-solving to proactive risk management. By identifying potential supplier issues, compliance risks, or spending anomalies early, organizations can address problems before they escalate into crises.

Key Trends Shaping the Future

Several converging trends are accelerating the adoption of predictive procurement automation, each addressing specific pain points while collectively transforming the procurement landscape.

AI-Driven Spend Forecasting

Traditional budgeting treats procurement spending as a relatively static line item, adjusted annually with modest inflation factors. AI-driven forecasting recognizes that procurement needs fluctuate dynamically based on business activity, market conditions, and operational patterns. Machine learning models analyze historical spending alongside business drivers—production volumes, sales forecasts, headcount changes—to generate rolling forecasts that update continuously.

This capability proves particularly valuable for industries with volatile demand or complex supply chains. Rather than discovering budget shortfalls mid-quarter, finance teams receive early warnings when spending trends diverge from projections, enabling proactive adjustments.

Smart Purchase Order Automation

Smart PO automation transcends simple workflow automation by incorporating contextual intelligence. These systems understand not just whether a requisition follows rules, but whether it makes sense given current circumstances. A requisition for seasonal items placed off-season triggers review. Orders for specialized equipment that duplicate recent purchases prompt verification. Price variations beyond normal ranges automatically initiate supplier confirmation.

This contextual awareness dramatically reduces exception handling. Rather than routing ambiguous cases to procurement analysts, smart systems resolve straightforward issues autonomously and escalate only genuinely complex scenarios with relevant context and recommendations.

Autonomous Sourcing Intelligence

Emerging AI capabilities are beginning to automate aspects of strategic sourcing traditionally requiring human judgment. Autonomous sourcing agents can monitor supplier marketplaces, identify potential new vendors matching specific criteria, and even conduct preliminary negotiations within predefined parameters.

While human oversight remains essential for significant commitments, these systems excel at managing long-tail procurement—the thousands of small-value purchases that consume disproportionate administrative effort. By handling routine sourcing autonomously, they free procurement professionals to focus on strategic supplier relationships and complex negotiations.

Integrated Compliance Engines

Regulatory compliance represents a growing challenge as procurement spans multiple jurisdictions, each with distinct requirements. Predictive compliance engines continuously monitor regulatory changes, automatically updating validation rules and flagging transactions that might violate new requirements.

More sophisticated systems can predict compliance risks before they materialize. By analyzing spending patterns, supplier characteristics, and regulatory trends, they identify areas where organizations face elevated compliance risk and recommend proactive measures.

Conversational Procurement Interfaces

Natural language interfaces are transforming how users interact with procurement systems. Rather than navigating complex enterprise software, users can describe their needs conversationally: "I need office supplies for the new Seattle office" or "Find backup suppliers for our primary circuit board vendor." The system interprets intent, retrieves relevant information, and guides users through procurement processes using plain language.

This accessibility reduces training requirements and accelerates adoption, particularly important as procurement touches employees across the organization, not just specialized procurement professionals.

The Business Case for Predictive Procurement Automation

The compelling case for predictive procurement automation rests on both tangible and intangible benefits. While specific outcomes vary by organization, common value drivers consistently emerge across implementations.

Operational Excellence Through Intelligence

Process cycle times compress substantially when systems anticipate needs and resolve routine issues autonomously. Purchase requisitions that once required multiple approval rounds flow through systems smoothly when predictive validation confirms compliance before human review. Invoice processing accelerates when systems predict and resolve matching discrepancies automatically.

Beyond speed, accuracy improvements reduce costly errors. Predictive validation catches problems before commitments are made—budget overruns before orders are placed, duplicate purchases before invoices are processed, non-compliant vendors before contracts are signed. Each prevented error avoids not just correction costs but potential operational disruptions.

Strategic Financial Impact

Working capital management improves when procurement spending becomes predictable. Finance teams can optimize payment timing, negotiate dynamic discounting arrangements with confidence, and maintain leaner cash reserves without risking liquidity crunches. The ability to forecast spending accurately transforms treasury management from reactive to strategic.

Supplier relationship management evolves from transactional to strategic when organizations can identify high-value partnerships and investment opportunities. Predictive analytics reveal which suppliers consistently deliver exceptional value, which relationships face emerging risks, and where deepening partnerships might yield mutual benefits.

Risk Mitigation and Resilience

Perhaps the most significant but difficult-to-quantify benefit involves risk avoidance. Supply chain disruptions, compliance violations, and fraud attempts all carry substantial costs—financial penalties, operational disruptions, reputational damage. Predictive systems that identify and mitigate these risks before they materialize create enormous value that never appears in traditional ROI calculations.

Organizations implementing predictive procurement report enhanced resilience—the ability to adapt quickly to market changes, supplier issues, or internal disruptions. This agility proves increasingly valuable in volatile business environments where competitive advantage often depends on responsiveness.

How Hyperbots Enables Predictive Procurement Automation

Hyperbots' approach to predictive procurement automation reflects a fundamental rethinking of how AI should integrate with financial operations. Rather than bolting intelligence onto legacy systems, Hyperbots built its platform around an AI-native architecture designed specifically for predictive capabilities.

Inside the Hyperbots Predictive Engine

The Hyperbots Procurement Co-Pilot operates as an intelligent assistant that understands not just procurement rules but business context. It continuously learns from every transaction, approval decision, and supplier interaction, refining its understanding of organizational preferences and priorities.

The system's predictive capabilities span multiple dimensions. Spend forecasting combines historical analysis with real-time business signals, generating rolling forecasts that update as conditions change. Supplier risk assessment evaluates multiple indicators—payment history, delivery performance, financial health signals—to provide early warning of potential issues.

Smarter Purchase Orders, Fewer Exceptions

Traditional procurement systems generate exceptions when transactions deviate from rigid rules. Hyperbots' contextual intelligence distinguishes between meaningful deviations requiring attention and routine variations that can be processed automatically. A seasonal purchase that looks unusual in isolation makes perfect sense when the system understands business cycles. A price increase that might trigger review gets approved automatically when the system recognizes market-wide inflation.

This contextual awareness dramatically reduces the exception queues that bog down procurement teams, allowing them to focus on genuinely complex decisions while routine transactions flow through automatically.

The platform integrates seamlessly with existing ERP systems, enhancing rather than replacing current infrastructure. This approach accelerates implementation and reduces disruption, allowing organizations to gain predictive capabilities without wholesale system replacements.

Implementation Best Practices

Successfully implementing predictive procurement automation requires thoughtful planning and phased execution. Organizations that achieve the greatest value follow several common patterns.

Laying the Foundation for Predictive Procurement

Data quality determines predictive accuracy. Before deploying advanced analytics, organizations must ensure their procurement data is clean, complete, and consistently structured. This includes standardizing supplier records, normalizing product categories, and enriching transaction data with relevant context.

Master data management often represents the most time-consuming aspect of implementation, but it's also the most critical. Without quality data, even sophisticated algorithms produce unreliable predictions.

Building AI Literacy Within Finance Teams

Successful adoption requires helping finance and procurement professionals understand how predictive systems work and how to interpret their insights. This doesn't mean turning them into data scientists, but rather building intuition about when to trust predictions, how to validate recommendations, and where human judgment remains essential.

Organizations that invest in training and change management achieve adoption rates far exceeding those that treat predictive automation as purely technical implementation.

Scaling AI Adoption Across Finance Functions

Smart organizations start with focused use cases that deliver clear value quickly—perhaps automating routine PO approvals or predicting supplier delivery delays. Early wins build credibility and provide learning opportunities before expanding to more complex scenarios.

As teams gain experience and confidence, they progressively tackle more sophisticated applications: strategic sourcing optimization, contract term negotiations, supplier portfolio rebalancing. This phased approach allows organizations to develop capabilities progressively while delivering continuous value.

The Future is Predictive: A Strategic Outlook

Procurement automation has reached an inflection point. The question is no longer whether to adopt predictive capabilities but how quickly organizations can implement them effectively. As predictive systems become more sophisticated and accessible, the competitive advantage shifts from those who automate to those who anticipate.

Forward-thinking organizations recognize that predictive procurement automation represents more than operational improvement—it fundamentally transforms how finance and procurement create value. By shifting from reactive processing to proactive management, these functions evolve from cost centers to strategic advisors, providing insights that inform business strategy.

The pathway forward involves embracing AI not as a replacement for human judgment but as an amplifier of human capabilities. Predictive systems handle routine decisions with speed and consistency, freeing professionals to focus on strategic relationships, complex negotiations, and innovative approaches to value creation.

Organizations adopting platforms like Hyperbots are already experiencing this transformation, gaining visibility, control, and strategic foresight that redefine what's possible in procurement management. The future of procurement isn't just automated—it's predictive, adaptive, and strategically indispensable.