What's the Cost to Process a Purchase Order? Benchmarks and Calculator

Uncover industry benchmarks and use our calculator to estimate the true cost to process a purchase order, discover how automation cuts expenses by up to 80%.

Executive Summary

The cost to process a purchase order represents one of the most significant operational expenses in modern procurement operations, yet many organizations lack clear visibility into these hidden costs. With manual processing averaging between $75-$150 per purchase order according to recent Deloitte procurement studies, finance leaders are increasingly seeking automated solutions to reduce these expenses.

Understanding the true cost of processing a purchase order is crucial for CFOs and procurement heads aiming to optimize their financial operations. This comprehensive guide examines industry benchmarks, provides calculation methodologies, and explores how AI-powered automation can deliver up to 80% cost reductions in purchase order processing.

Understanding Purchase Order Processing Costs

What Constitutes Purchase Order Processing Costs?

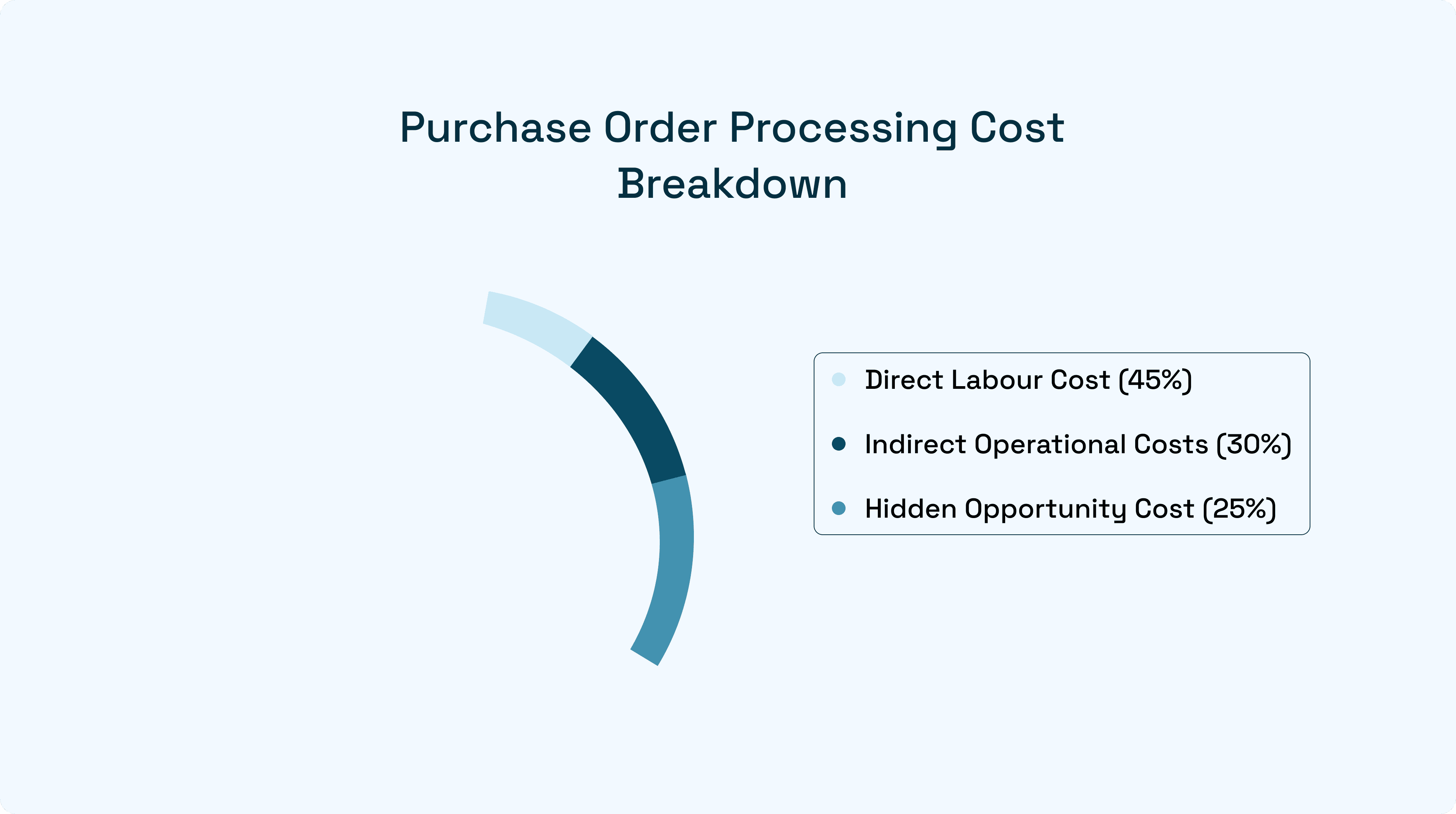

The average cost to process a purchase order encompasses multiple direct and indirect expenses that organizations often overlook. These costs include:

Direct Labor Costs:

Procurement specialist time for order creation and review

Approval workflow processing by multiple stakeholders

Data entry and system updates

Vendor communication and coordination

Exception handling and error correction

Indirect Operational Costs:

System maintenance and licensing fees

Training and onboarding expenses

Compliance and audit requirements

Storage and document management

Delayed processing penalties and rush fees

Hidden Opportunity Costs:

Lost early payment discounts

Delayed project timelines due to processing bottlenecks

Resource allocation inefficiencies

Strategic procurement activities foregone for tactical processing

Research from Aberdeen Group indicates that best-in-class organizations achieve 65% lower processing costs through automation compared to laggard companies.

Industry Benchmarks: Average Cost of Processing a Purchase Order

Current Market Benchmarks

The average cost of processing a purchase order varies significantly across industries and organization sizes. Based on comprehensive market research and client data:

By Organization Size:

Small businesses (< 100 employees): $45-$85 per PO

Mid-market companies (100-1,000 employees): $65-$120 per PO

Large enterprises (1,000+ employees): $85-$175 per PO

By Processing Method:

Fully manual processing: $125-$200 per PO

Semi-automated systems: $75-$125 per PO

AI-powered automation: $15-$35 per PO

By Industry Vertical:

Manufacturing: $95-$145 per PO

Healthcare: $105-$165 per PO

Technology: $85-$135 per PO

Retail: $65-$115 per PO

Financial Services: $110-$180 per PO

These benchmarks highlight the significant variation in how much it costs to process a purchase order depending on organizational factors and technology adoption levels.

Factors Influencing Processing Cost

Several key factors determine where an organization falls within these benchmark ranges:

Process Complexity: Organizations with multi-level approval workflows, complex vendor requirements, and extensive compliance needs typically experience higher processing costs. Each additional approval step can add $8-$15 to the total cost per purchase order.

Technology Infrastructure: Legacy ERP systems without modern procurement modules often require manual workarounds that increase processing time by 40-60%. Organizations using disconnected systems face additional data reconciliation costs.

Vendor Relationship Management: Companies maintaining relationships with numerous vendors face higher communication and coordination costs. Best-practice organizations reduce vendor bases by 20-30% to streamline processing.

Exception Handling Rate: Purchase orders requiring manual intervention or corrections can cost 3-5 times more to process than standard orders. High exception rates indicate process inefficiencies or inadequate system capabilities.

Purchase Order Processing Cost Calculator

Calculate Your Organization's Costs

To determine your specific cost to process a purchase order, use this comprehensive calculation framework:

Step 1: Labor Cost Calculation

Annual PO Processing Hours = (Number of POs × Average Hours per PO)

Total Labor Cost = (Processing Hours × Blended Hourly Rate) + (Management Oversight Hours × Management Rate)

Step 2: Technology and Infrastructure Costs

Annual Technology Costs = Software Licenses + System Maintenance + Integration Costs + Training Expenses

Cost per PO = Annual Technology Costs ÷ Annual PO Volume

Step 3: Indirect Cost Attribution

Indirect Costs per PO = (Facilities + Utilities + Administrative Overhead) × Processing Time Allocation Percentage

Step 4: Total Cost per Purchase Order

Total Cost per PO = Direct Labor Costs + Technology Costs + Indirect Costs + Exception Handling Premiums

Example Calculation for Mid-Market Company:

Annual PO Volume: [X] purchase orders

Average Processing Time: [Current hours] per PO

Blended Labor Rate: $[Y]/hour

Technology Costs: $[Z] annually

Indirect Cost Allocation: [%] of direct costs

Total Cost per PO = ([Labor Rate] × [Processing Hours]) + ([Annual Tech Costs] ÷ [PO Volume]) + ([%] overhead)

With Hyperbots automation: Up to 80% reduction in total processing costs

Cost Optimization Opportunities

Organizations can identify immediate cost reduction opportunities by analyzing their current cost of processing a purchase order against these optimization levers:

Process Standardization (10-25% reduction):

Implement standardized purchase order templates

Establish consistent approval workflows

Create vendor scorecards and preferred supplier programs

Technology Upgrades (30-50% reduction):

Deploy modern procurement platforms

Integrate with existing ERP systems

Implement automated approval routing

AI-Powered Automation (60-80% reduction):

Leverage machine learning for smart routing

Automate data extraction and validation

Enable predictive analytics for demand planning

The Hidden Impact of High Processing Costs

Beyond the Direct Financial Impact

High purchase order processing costs create cascading effects throughout the organization that extend far beyond the immediate financial burden:

Strategic Procurement Limitations: When procurement teams spend 70-80% of their time on tactical processing activities, strategic initiatives suffer. Organizations miss opportunities for cost savings through strategic sourcing, supplier consolidation, and contract optimization.

Cash Flow Disruption: Extended processing times delay vendor payments, potentially forfeiting early payment discounts worth 2-3% of purchase value. For organizations processing $10 million in annual purchases, this represents $200,000-$300,000 in lost savings.

Compliance and Risk Exposure: Manual processes increase the likelihood of errors, duplicate payments, and compliance violations. The average cost to resolve a duplicate payment exceeds $350 per incident, not including potential audit findings and penalties.

Vendor Relationship Strain: Slow, error-prone purchase order processing damages vendor relationships, potentially leading to less favorable terms, reduced service levels, and limited access to innovative products or services.

Revolutionary Purchase Order Automation with Hyperbots AI Co-pilots

Transforming Procurement Operations Through AI

Hyperbots delivers the most comprehensive suite of AI Co-pilots specifically designed for purchase order automation, enabling organizations to reduce operational costs by up to 80%. The platform's Procurement Co-pilot revolutionizes traditional purchase order processing by eliminating manual bottlenecks and delivering intelligent automation at every step.

Core Capabilities:

Intelligent Request Processing: AI-powered analysis converts purchase requests into optimized purchase orders within minutes

Smart Approval Routing: Dynamic workflow management ensures requests reach appropriate approvers based on amount, category, and organizational policies

Real-time ERP Synchronization: Seamless integration maintains data consistency across all enterprise systems

Predictive Spend Analytics: Advanced analytics provide finance teams with real-time visibility into spending patterns and budget utilization

The Procurement Co-pilot shrinks cycle times from days to hours, freeing procurement teams from repetitive manual tasks while ensuring compliance and cost-effectiveness.

Differentiation in the Procure-to-Pay Market

How Hyperbots Stands Apart

While traditional procure-to-pay solutions focus on workflow automation, Hyperbots leverages advanced AI to deliver intelligent decision-making that fundamentally transforms how organizations approach purchase order processing:

AI-First Architecture: Unlike competitors who retrofit AI capabilities onto legacy platforms, Hyperbots built its solution from the ground up with artificial intelligence at its core. This approach enables more sophisticated automation scenarios and continuous learning from organizational patterns.

Contextual Intelligence: Hyperbots' AI understands business context beyond simple rules-based automation. The platform considers historical spending patterns, vendor performance, budget constraints, and regulatory requirements when processing purchase orders, reducing the average cost to process a purchase order through intelligent decision-making.

Adaptive Learning: The platform continuously learns from organizational behavior, automatically refining approval routing, vendor selection recommendations, and exception handling procedures. This self-improving capability ensures long-term cost optimization without ongoing manual configuration.

Zero-Touch Processing: Hyperbots achieve industry-leading straight-through processing rates of 80% for routine purchase orders, compared to 40-60% for traditional solutions. This capability dramatically reduces the cost of processing a purchase order by minimizing human intervention requirements.

Best Practices for Reducing Purchase Order Processing Costs

Immediate Implementation Strategies

Organizations can begin reducing their cost to process a purchase order through strategic best practices:

Process Optimization:

Standardize purchase order templates and approval workflows

Implement spend thresholds for streamlined processing

Create preferred vendor catalogs with pre-negotiated terms

Establish clear exception handling procedures

Technology Leverage:

Deploy electronic purchase order systems with mobile approval capabilities

Integrate procurement platforms with existing ERP and financial systems

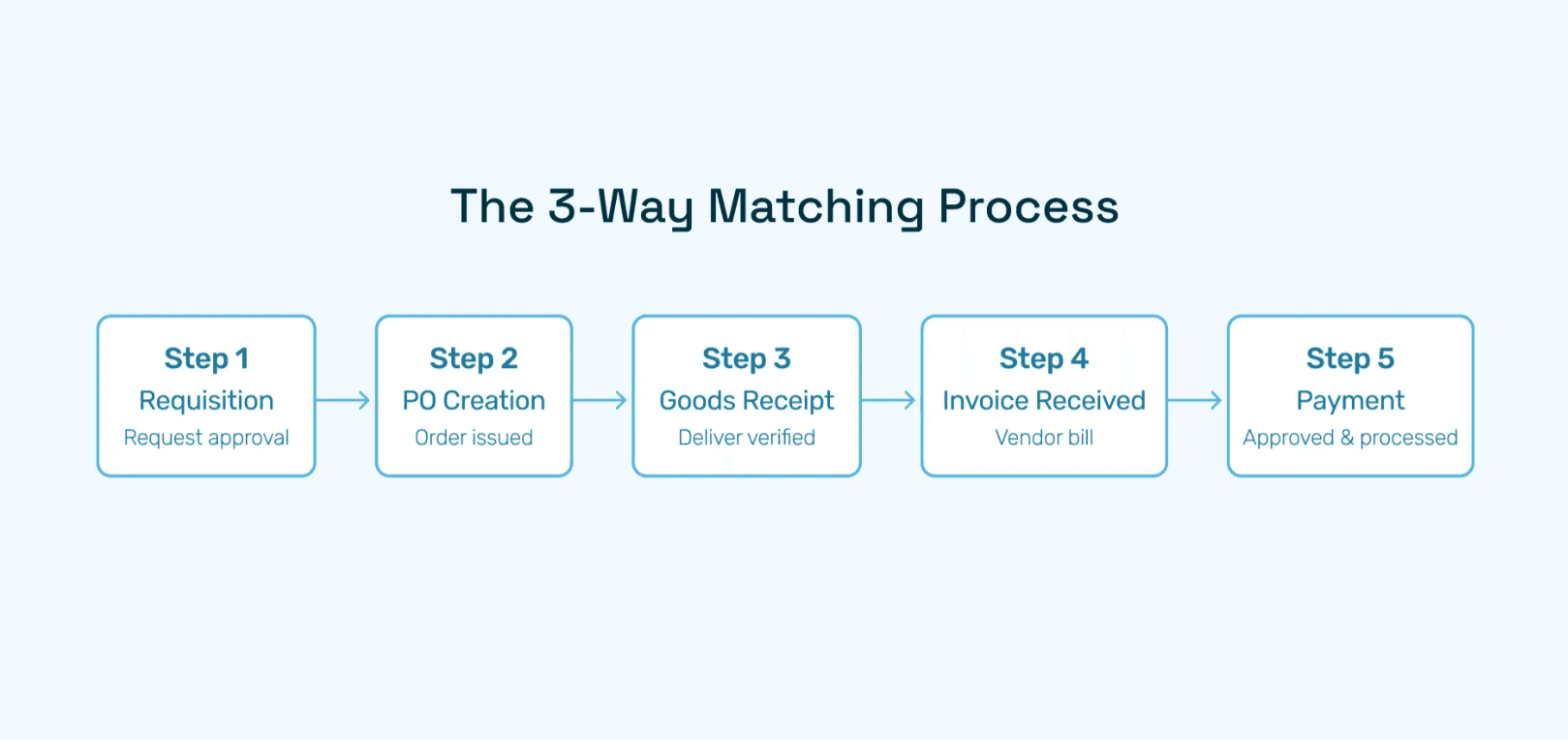

Implement automated three-way matching for invoices, receipts, and purchase orders

Utilize analytics dashboards for real-time spend visibility

Organizational Alignment:

Train stakeholders on efficient requisition practices

Establish clear roles and responsibilities for purchase order processing

Create vendor scorecards for performance monitoring

Implement regular process reviews and optimization cycles

Long-term Strategic Considerations

Sustainable cost reduction requires ongoing attention to strategic procurement transformation:

AI and Automation Investment: Organizations achieving the lowest average cost of processing a purchase order invest in comprehensive AI-powered solutions that eliminate manual touchpoints while maintaining control and compliance.

Vendor Relationship Management: Strategic vendor partnerships reduce processing complexity and create opportunities for volume-based pricing advantages and streamlined ordering procedures.

Continuous Improvement Culture: Best-practice organizations establish regular review cycles to identify new optimization opportunities and measure progress against industry benchmarks.

Taking Action: Transform Your Purchase Order Processing

Understanding the cost to process a purchase order is only the first step toward procurement transformation. Organizations serious about reducing operational expenses while improving efficiency should evaluate comprehensive AI-powered solutions that address root causes rather than symptoms.

Hyperbots' Procurement Co-pilot represents the next generation of purchase order automation, delivering unprecedented cost reductions while enhancing control, compliance, and strategic value creation. The platform's AI-first approach ensures continuous improvement and adaptation to changing business requirements.

Ready to discover how much your organization could save? Explore Hyperbots' Procurement Co-pilot solution or schedule a personalized demonstration to see the platform in action with your specific purchase order processing scenarios.

Frequently Asked Questions

Q: What is the typical cost to process a purchase order manually?

A: Manual purchase order processing typically costs between $125-$200 per purchase order, depending on organization size, complexity, and efficiency. This includes direct labor, system costs, and indirect operational expenses.

Q: How much can AI automation reduce purchase order processing costs?

A: AI-powered automation solutions like Hyperbots can reduce purchase order processing costs by 80%, bringing the average cost to process a purchase order down per order through intelligent automation and exception handling.

Q: What factors most significantly impact purchase order processing costs?

A: The most significant cost drivers include manual processing time, exception handling rates, approval workflow complexity, system integration capabilities, and vendor management efficiency.

Q: How do I calculate ROI for purchase order automation investments?

A: Calculate ROI by comparing current processing costs (volume × cost per PO) against projected costs with automation, then factor in productivity gains, compliance improvements, and early payment discount capture opportunities.

Q: What's the difference between basic automation and AI-powered solutions?

A: Basic automation handles routine tasks through rules-based workflows, while AI-powered solutions like Hyperbots provide intelligent decision-making, continuous learning, and adaptive optimization that delivers superior cost reduction and efficiency gains.