Why Manufacturing Teams Should Choose Hyperbots Over Tipalti for Accounts Payable Automation

See why Hyperbots outperforms Tipalti with autonomous AP, deeper ERP alignment, and manufacturing-grade AI intelligence.

Finance automation has become essential for modern mid-market companies navigating rising invoice volumes, multi-plant operations, complex supply chains, and the pressure to close books faster. In manufacturing, where procurement, goods receipts, and vendor payments intersect daily, traditional workflow-based AP tools are no longer enough. This is where decision-makers often compare established players like Tipalti with modern autonomous finance platforms like Hyperbots.

This blog breaks down the differences, helping manufacturing CFOs, Controllers, and Finance Managers evaluate the best Tipalti alternative for manufacturing, with a specific lens on accuracy, autonomy, ERP alignment, and manufacturing-grade AP complexity.

Tipalti Overview: What They Offer in Accounts Payable Automation

Tipalti is a well-known AP automation platform designed to streamline invoice processing, supplier management, global payments, PO matching, tax compliance, and payment reconciliation. Their solution is commonly adopted by mid-market finance teams looking to standardize workflows and centralize vendor operations.

Key Capabilities of Tipalti’s Accounts Payable Suite

Invoice Management: OCR-based invoice capture with automated field extraction, validation checks, and multi-level approvals. Invoices are stored in a centralized repository for easier tracking.

PO Matching: Supports standard 2-way/3-way matching for price, quantity, and receipt alignment to reduce duplicates and mismatches.

Supplier Management: Self-service onboarding with W-8/W-9 collection, global data validation, and sanctions screening to maintain compliant vendor records.

Global Payments: Enables cross-border payments across 200+countries and 120 currencies, managing FX, scheduling, and vendor notifications.

Automated Tax Compliance: Built-in tax engine for form validation, withholding rules, and IRS reporting to support compliant AP operations.

Payment Reconciliation: Automatically matches remittances, fees, and FX differences to ERP records for clearer cash-movement visibility.

Procurement: Provides PO creation workflows, vendor catalogues, and spend-policy enforcement to improve purchasing discipline.

Expense Management: Supports employee reimbursements with receipt capture, policy enforcement, and approval routing.

Tipalti’s Positioning in Manufacturing & Their Limitations

Based on Tipalti’s manufacturing AP, the product is positioned to help manufacturers reduce manual invoice entry, streamline 2-way/3-way matching, minimize supplier payment delays, and improve visibility across multiple plants or production sites. For manufacturing teams with relatively standardized procurement cycles, Tipalti’s workflow automation can deliver efficiency and control.

However, manufacturing Accounts Payable processes typically involve deeper operational complexity that workflow-based tools don't fully address, especially at scale.

These include:

Multi-line raw material POs with dozens or hundreds of line items.

GRN-based invoice variances due to receiving discrepancies across warehouses or plants.

Partial receipts and backorders that require logic-based matching, not static rules.

BOM-level cost structures, where item-level accuracy directly affects Cost of Goods Sold (COGS).

Plant-level vendor validation to manage diverse suppliers, logistics partners, and OEM vendors.

Month-end Goods Received Not Invoiced (GRNI) accruals require automated reasoning, not just workflow routing.

These realities create gaps for teams evaluating AP automation for manufacturing, particularly when scalability, accuracy, and ERP synchronization are must-have requirements rather than add-ons.

Hyperbots: Agentic AI Built for Finance & Accounting

Manufacturing AP teams face multi-plant complexity, multi-line POs, GRN variances, partial receipts, BOM level items, accruals and global vendor networks. Hyperbots has’ six AP‐focused Co-Pilots built for exactly those challenges, and here’s how they map directly to manufacturing needs and outperform Tipalti’s standard suite.

Invoice Processing Co-Pilot

Hyperbots Invoice Processing Co-Pilot automates invoice discovery, extraction, validation, matching and GL posting in under a minute, with up to 80% straight-through processing.

It supports multi-page, multi-line invoices, extracting 140+ fields including line‐items, dates, terms, and addresses.

For manufacturing, where a raw material PO may have dozens of line items, partial receipts, or Bill of Materials (BOM) components, this level of detail matters.

It offers full 3-way matching (invoice vs PO vs GRN) and configurable matching strategies (2-way or 3-way) with smart tolerances.

Compared to Tipalti’s standard 2-way/3-way matching for quantity/price/receipt, Hyperbots goes deeper, reasoning across many more fields, supporting complex POs, backorders, and manufacturing‐specific formats.

Accruals Co-Pilot

Hyperbots’ Accruals Co-Pilot automates the detection of pending invoices or goods received but not invoiced (GRNI), books accruals, and posts reversals when the actual invoice arrives.

It supports custom accrual cut-offs (daily/weekly/monthly), policy configuration for goods vs services, and multi-entity/multi-plant ERP environments.

For manufacturing teams dealing with raw material receipts, incomplete invoices, and month-end pressure to accrue accurately, this is a major differentiator. Tipalti lacks a dedicated, autonomous accrual engine built for these manufacturing-centric accrual dynamics.

Procurement Co-Pilot

Hyperbots Procurement Co-Pilot automates purchase requisition creation, PO generation and dispatch, validation of contract data, budget checks, and merges procurement and AP workflows closely.

It supports custom PO templates, PR/PO field configurability, duplicate PR/PO detection, and vendor portal visibility.

In manufacturing, where procurement ties tightly to inventory, BOMs, tooling, MRO spares, and cost centres, this close alignment of procurement and AP is critical.

Tipalti offers PO creation workflows and PO matching, but the integration of procurement and AP, and the intelligent PR/PO automation, is stronger in Hyperbots.

Vendor Management Co-Pilot

Hyperbots’ Vendor Management Co-Pilot automates onboarding, verifies vendor identity (W-9/W-8 forms, etc.), detects duplicate vendor records, and provides a supplier portal with live PO/invoice/payment status.

For manufacturing teams managing large and global supplier networks (OEMs, contract manufacturers, logistics vendors), supplier master data quality and vendor portal transparency are key.

Tipalti offers self-service supplier onboarding, W-8/W-9 collection and sanctions screening, but typically remains more focused on compliance onboarding, less on vendor portal visibility and continuous master data hygiene tailored to manufacturing networks.

Payments Co-Pilot

Hyperbots’ Payments Co-Pilot analyses payment terms, discounts, cash flow, penalty risk, optimises payment timing, posts to ERP, and offers real-time compliance and audit trails.

Tipalti supports global payments and payment reconciliation, which is strong, but lacks the deeper AI-based optimisation of payment timing and cash-flow intelligence built for manufacturing scale.

Hyperbots combines the intelligence of payment timing with full integration, thereby optimizing cash flow, capturing early payment discounts with raw material suppliers, and managing multi-currency payments across plants.

Sales Tax Verification Co-Pilot

Hyperbots Sales Tax Verification Co-Pilot automates line-item tax categorisation, origin & destination address extraction, live tax dictionaries, nexus thresholds, audit-trail generation, and integrates tax validation into the invoice workflow in real time.

For manufacturing companies with multi-jurisdiction sourcing, complex goods flows, exempt goods, and multi-state/federal tax regimes, this level of tax automation is highly relevant.

Tipalti offers tax compliance (form validation, withholding, FATCA) primarily for vendor-side tax, but may not provide the same line-item, origin-destination, live tax-dictionary, manufacturing‐supply-chain aware tax logic that Hyperbots delivers.

Why These Features Matter for Manufacturing Teams

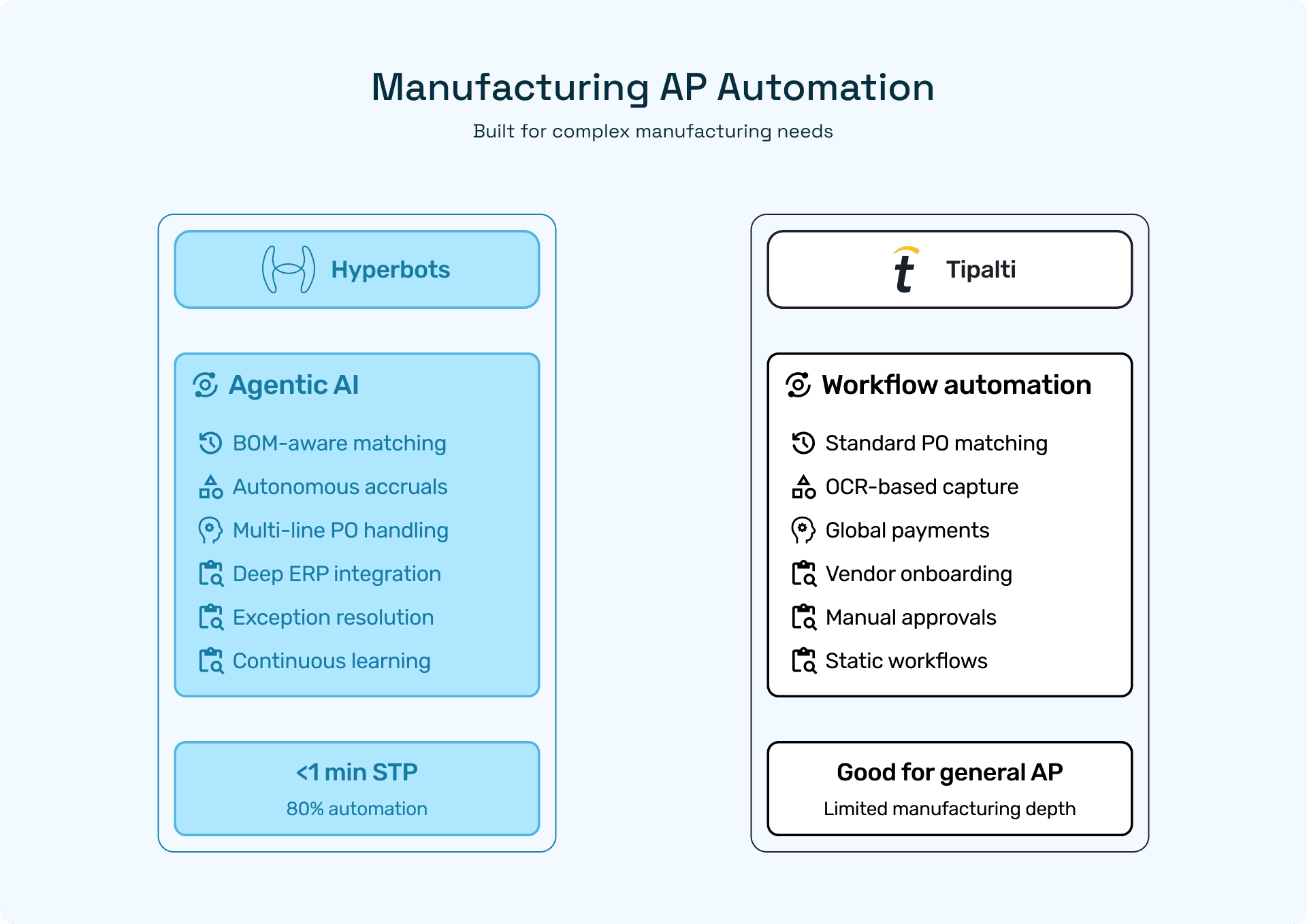

Manufacturing AP is more complex: multi-line, BOM-aware, GRN variances, partial receipts, multi-plant cost centres, accruals, supplier networks, and global tax rules.

Tipalti’s strength lies in workflow automation and standard AP processes (invoice capture, PO matching, global payments, tax forms). But its automation is less tailored for manufacturing-specific complexities.

Hyperbots delivers deep domain automation via Agentic AI, tuned for manufacturing: intelligent invoice/PO/GRN matching, accrual automation, procurement/AP convergence, vendor master hygiene, payment timing intelligence, and line‐item tax validation, all built with manufacturing workflows in mind.

Hence, manufacturing teams choosing an AP automation tool will gain far more value from a platform that understands their complexity and embeds reasoning intelligence, which is Hyperbots - better than one built for standard AP workflows, Tipalti.

Feature-by-Feature Comparison: Hyperbots vs Tipalti for Manufacturing

Category | Hyperbots | Tipalti |

AI Type | Agentic AI for Finance & Accounting. Learns from workflows, GL logic, and invoice patterns. | OCR + workflow automation. Limited learning. |

Manufacturing PO Matching | Item-level, BOM-aware, multi-line matching; handles partial receipts + revisions. | Standard 2-way/3-way numeric matching. |

Accruals | Autonomous GRNI accrual engine with reversal and real-time ERP sync. | No autonomous accrual engine. |

Vendor Management | Continuous monitoring + ERP master synchronization. | One-time onboarding checks. |

Decision Intelligence | Predictive suggestions, exception resolution, and reasoning-based posting. | Workflow routing + visibility. |

Integrations | Deep ERP read/write of item master, COA, vendor master, and custom fields | Sync-based integrations do not reason with ERP structures. |

Sales Tax Verification | Line-level tax validation, jurisdiction checks, anomaly detection. | Limited to tax form collection and withholding rules. |

Learning & Adaptation | Learns from corrections, vendor behavior, and historical postings. | Static rules/workflows. |

Autonomy Level | End-to-end autonomous processing in <1 min STP. | Requires manual approvals and exception resolution. |

Where Hyperbots Stands Out for Manufacturing

1. Handles Complex Manufacturing PO Structures

Manufacturing invoices are rarely simple; they include multi-line POs, BOM components, partial shipments, revisions, and supplier-specific formats.

Hyperbots’ Invoice Processing Co-Pilot can understand item-level detail, BOM logic, and GRN variances, enabling far more accurate 2-way/3-way matching than basic OCR workflows used by Tipalti.

2. Autonomous Accruals for GRNI

Manufacturers constantly deal with goods received but not invoiced across multiple plants and warehouses.

Hyperbots’ Accruals Co-Pilot automatically books, adjusts, and reverses GRNI accruals in real time, keeping COGS accurate and relieving month-end pressure. Tipalti has no autonomous accrual engine.

3. Cross-Plant Vendor Verification

Manufacturers work with large, diverse supplier networks.

Hyperbots’ Vendor Management Co-Pilot continuously validates vendor data, catches duplicates, and updates banking/tax details across entities, going beyond Tipalti’s one-time onboarding checks.

4. ERP-Deep Integrations Built for Manufacturing

Hyperbots reads and writes into cost centers, item masters, inventory records, GRNs, and custom ERP fields, ensuring plant-level accuracy and real-time postings. This depth of integration enables true straight-through processing, not just sync-based updates.

5. Autonomous Exception Resolution

Manufacturing AP faces constant mismatches, quantity differences, tax issues, price changes, backorders, and freight adjustments.

Hyperbots’ Agentic AI resolves most of these autonomously by learning vendor and plant-level patterns, whereas Tipalti routes exceptions back to users for manual intervention.

Why Hyperbots Is the Best Tipalti Alternative for Manufacturing

1. Designed for Manufacturing Complexity

Tipalti works well for general AP workflows, but manufacturing needs far deeper intelligence. Raw materials, Maintenance, Repair and Operations (MRO) supplies, tooling, and subcontracting invoices often contain dozens of line items, BOM components, partial receipts, and pricing changes.

Hyperbots is built specifically for these scenarios. Its Invoice Processing Co-Pilot interprets complex structures, understands item-level detail, and reconciles POs and GRNs even when quantities or formats vary, far beyond what OCR-based matching can handle.

2. True Autonomy vs. Workflow Automation

Tipalti automates steps; Hyperbots automates outcomes.

Instead of routing tasks through humans, Hyperbots’ Agentic AI reasons, learns, and executes work end-to-end, coding invoices, resolving exceptions, validating vendors, verifying taxes, and updating ERP data on its own.

This shifts manufacturing AP from semi-automated workflows to hands-off, autonomous processing.

3. Superior Speed & Accuracy

Manufacturing AP must keep pace with fast-moving supply chains.

Hyperbots delivers <1-minute STP, 99.8% accuracy, 80% STP and real-time ERP sync, ideal for plants handling high invoice volumes and time-sensitive supplier payments.

Tipalti improves efficiency but still relies on human approvals and manual intervention for exceptions.

4. Continuous Learning from Every Cycle

Manufacturing processes evolve quickly, new suppliers, changing lead times, shifting cost centers.

Hyperbots adapts automatically by learning from each cycle: vendor-specific patterns, recurring exceptions, plant-level purchasing behavior, and item-level logic. Tipalti’s workflows remain static unless manually updated.

5. Better Control, Compliance & Auditability

Hyperbots strengthens control with AI-driven tax checks, continuous vendor validation, duplicate detection, and ERP-level posting verification. This helps manufacturers reduce tax leakage, prevent payment errors, and maintain clean audit trails.

Tipalti focuses heavily on onboarding compliance but lacks continuous, AI-driven control across plants and suppliers.

Conclusion: Choosing Autonomous Finance Over Traditional Automation

Tipalti is a fair option for teams needing standardized AP workflows and global payments, but manufacturing requires more: systems that understand complex invoices, GRN fluctuations, plant-level nuances, and multi-entity purchasing.

Hyperbots delivers this through Agentic AI, offering autonomy, learning, deeper ERP integration, and real-time intelligence across AP, AR, and FP&A.

For manufacturers looking to eliminate manual work, accelerate processing, improve COGS accuracy, and scale AP without growing headcount, Hyperbots is the clear choice.

Explore how Hyperbots is redefining finance workflows and see it live in action.