Purchase Order Automation in Manufacturing

Maximize efficiency and minimize disruption: Discover the definitive strategies for leveraging modern Purchase Order (PO) automation to optimize factory procurement, enhance inventory control, and drive profitability across manufacturing operations in 2025.

Executive Summary

Manufacturing purchase order automation has emerged as a critical competitive advantage in 2025, with smart manufacturing solutions projected to reach $479.17 billion by 2029 and 52% of procurement teams having already adopted automation technologies. This comprehensive guide explores how artificial intelligence is revolutionizing factory procurement automation, enabling manufacturers to achieve up to 80% operational cost reductions while maintaining compliance and control.

Key insights covered include the transformative impact of AI-powered PO automation for industry, implementation strategies for factory procurement automation, and how modern platforms like Hyperbots are setting new standards for manufacturing efficiency and precision.

What is Manufacturing Purchase Order Automation?

Manufacturing purchase order automation represents the digitization and intelligent orchestration of procurement workflows specifically designed for industrial operations. Unlike generic procurement systems, manufacturing PO automation addresses unique challenges such as complex bill of materials (BOM) management, multi-location inventory synchronization, and regulatory compliance requirements.

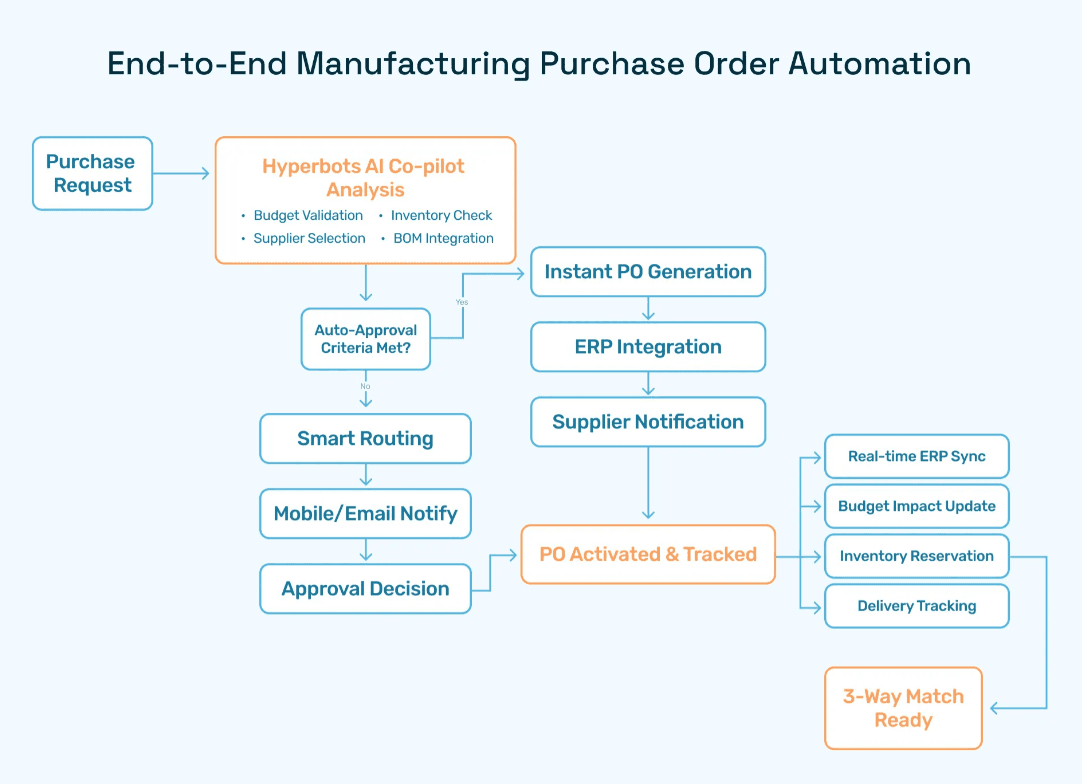

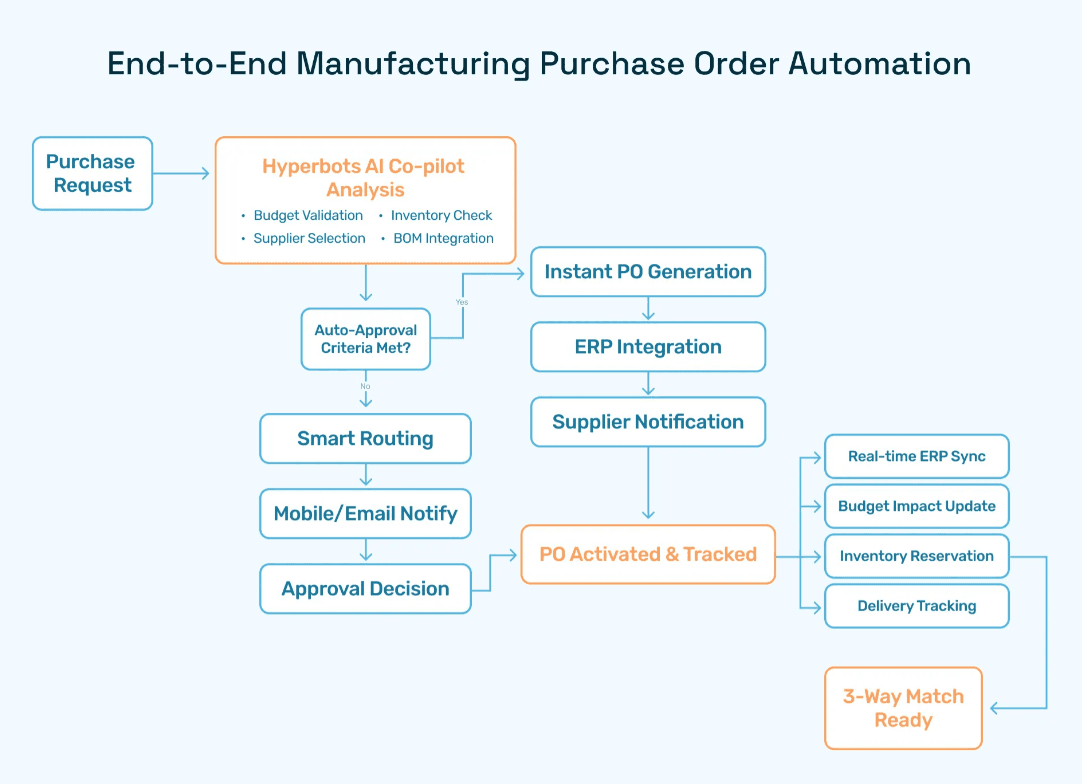

At its core, factory procurement automation eliminates manual purchase order creation, routing, and tracking through AI-powered workflows that integrate seamlessly with enterprise resource planning (ERP) systems, supplier portals, and manufacturing execution systems (MES).

Key Components of Modern PO Automation for Industry

Manufacturing purchase order automation encompasses several interconnected elements:

Intelligent Request Processing: AI algorithms automatically convert manufacturing requisitions into optimized purchase orders, accounting for inventory levels, lead times, and production schedules.

Smart Approval Routing: Dynamic workflows route purchase orders based on value thresholds, department budgets, and supplier risk assessments, ensuring appropriate oversight without bottlenecks.

Real-time ERP Integration: Seamless synchronization with manufacturing ERP systems provides instant visibility into budget utilization, inventory impacts, and delivery schedules.

Supplier Communication Automation: Automated notifications, acknowledgments, and status updates streamline vendor relationships while maintaining audit trails.

The Manufacturing Procurement Challenge

Manufacturing organizations face unique procurement complexities that generic automation solutions often fail to address effectively. These challenges have intensified as manufacturers embrace new technologies while addressing workforce training needs in an increasingly competitive landscape.

Traditional Pain Points in Factory Procurement

Manual Process Inefficiencies: Traditional paper-based or email-driven purchase order processes create significant delays in manufacturing environments where time-to-market directly impacts profitability. Manual data entry errors can cascade through production planning, causing costly delays and inventory mismatches.

Supplier Management Complexity: Manufacturing operations typically work with hundreds of suppliers across raw materials, components, maintenance supplies, and capital equipment. Managing different payment terms, quality requirements, and compliance standards manually becomes increasingly unmanageable.

Regulatory Compliance Burden: Manufacturing industries face stringent regulatory requirements for supplier qualification, documentation, and traceability. Manual compliance management exposes organizations to significant audit risks and potential penalties.

Inventory Optimization Challenges: Without real-time integration between procurement and production planning systems, manufacturers struggle to balance inventory carrying costs with stockout risks, particularly for critical production components.

The Cost of Inefficient Manufacturing Procurement

Research indicates that manual procurement processes in manufacturing environments typically consume 15-20% more resources than necessary, with procurement cycle times averaging 7-14 days for standard purchase orders. These inefficiencies compound when considering:

Lost early payment discounts due to delayed processing

Emergency procurement costs from stockouts

Supplier relationship strain from communication delays

Compliance audit findings and associated remediation costs

Benefits of Manufacturing Purchase Order Automation

The implementation of comprehensive factory procurement automation delivers transformational benefits across operational, financial, and strategic dimensions. Companies embracing digital procurement solutions report up to 30% efficiency gains, with leading manufacturers achieving even more substantial improvements through AI-powered platforms.

Operational Excellence Through Automation

Cycle Time Reduction: Advanced manufacturing purchase order automation platforms typically reduce procurement cycle times from days to hours. Hyperbots' Procurement Copilot achieves this through intelligent pre-validation of purchase requests, automated approval routing, and real-time ERP synchronization.

Error Elimination: AI-powered validation rules eliminate common data entry errors that plague manual processes. Automated cross-referencing against supplier catalogs, pricing agreements, and inventory systems ensures accuracy while reducing procurement team workload.

Process Standardization: Factory procurement automation enforces consistent workflows across multiple manufacturing locations, ensuring compliance with corporate procurement policies while accommodating local operational requirements.

Enhanced Visibility: Real-time dashboards provide procurement managers with instant visibility into spending patterns, supplier performance, and budget utilization across all manufacturing facilities.

Financial Impact and Cost Optimization

Direct Cost Savings: Organizations implementing comprehensive PO automation for industry typically achieve 15-25% reduction in procurement operating costs through elimination of manual labor, reduced errors, and improved supplier terms negotiation.

Working Capital Optimization: Intelligent payment timing optimization helps manufacturers balance cash flow management with early payment discount capture. Advanced platforms analyze payment terms across vendor portfolios to maximize financial benefits.

Inventory Carrying Cost Reduction: Integration with manufacturing planning systems enables just-in-time procurement strategies that reduce inventory carrying costs while maintaining production continuity.

Compliance Cost Avoidance: Automated audit trails and compliance monitoring significantly reduce the risk and cost of regulatory violations in heavily regulated manufacturing sectors.

Strategic Competitive Advantages

Supplier Relationship Enhancement: Automated communication and performance tracking enable stronger supplier partnerships through improved transparency, faster issue resolution, and data-driven collaboration.

Scalability Without Complexity: As manufacturing operations expand, automated procurement systems scale seamlessly without proportional increases in administrative overhead or process complexity.

Data-Driven Decision Making: Comprehensive analytics enable procurement teams to identify cost optimization opportunities, assess supplier risk, and make strategic sourcing decisions based on real-time data rather than historical reports.

Core Features of Manufacturing PO Automation Systems

Modern factory procurement automation platforms incorporate sophisticated capabilities specifically designed for manufacturing environments. These systems go far beyond basic purchase order generation to provide comprehensive procurement orchestration.

Intelligent Purchase Requisition Processing

AI-Powered Request Analysis: Advanced natural language processing algorithms analyze purchase requisitions to automatically categorize requests, identify preferred suppliers, and suggest optimal procurement strategies based on historical data and current market conditions.

BOM Integration: Direct integration with engineering systems enables automatic conversion of bill of materials changes into procurement actions, ensuring production continuity while optimizing supplier selection.

Budget Validation: Real-time budget checking against departmental allocations, project codes, and annual procurement plans prevents overruns while maintaining operational flexibility.

Dynamic Approval Workflows

Intelligent Routing: Machine learning algorithms analyze purchase characteristics, urgency indicators, and organizational hierarchy to route approvals through optimal paths that balance control with speed.

Exception Management: Automated exception handling identifies unusual procurement patterns, pricing variances, or supplier issues that require human intervention, while allowing routine transactions to flow through automatically.

Mobile Accessibility: Cloud-based approval interfaces enable manufacturing managers to review and approve purchase orders from anywhere, preventing delays due to travel or remote work arrangements.

Advanced Supplier Management

Performance Monitoring: Continuous tracking of supplier delivery performance, quality metrics, and responsiveness enables data-driven supplier selection and relationship management.

Risk Assessment: AI algorithms analyze supplier financial stability, regulatory compliance status, and operational capacity to provide real-time risk scores that inform procurement decisions.

Contract Management: Automated contract compliance monitoring ensures purchase orders align with negotiated terms while flagging opportunities for contract renewals or renegotiations.

Integration and Connectivity

ERP Synchronization: Real-time bidirectional integration with manufacturing ERP systems ensures purchase orders immediately impact financial reporting, inventory planning, and production scheduling.

Supplier Portal Integration: Direct connectivity with supplier systems enables electronic order transmission, acknowledgment, and status updates that eliminate manual communication overhead.

Manufacturing Execution System (MES) Integration: Advanced platforms integrate with MES platforms to align procurement timing with actual production schedules, optimizing inventory levels and reducing carrying costs.

Implementation Strategies for Factory Procurement Automation

Successful implementation of manufacturing purchase order automation requires careful planning, stakeholder engagement, and phased deployment strategies that minimize disruption to ongoing manufacturing operations.

Pre-Implementation Assessment

Process Mapping and Analysis: Comprehensive analysis of existing procurement workflows identifies optimization opportunities and potential integration challenges before system deployment begins.

Stakeholder Requirements Gathering: Engagement with procurement teams, manufacturing managers, finance departments, and IT staff ensures the automation platform addresses all organizational needs and compliance requirements.

Supplier Readiness Evaluation: Assessment of key suppliers' technical capabilities and willingness to participate in automated procurement processes helps identify potential implementation barriers and required support.

Phased Deployment Approach

Pilot Program Development: Starting with a limited scope pilot program allows organizations to validate system functionality, refine workflows, and build user confidence before full-scale deployment.

Category-Based Rollout: Sequential implementation across different procurement categories (maintenance supplies, raw materials, capital equipment) enables focused change management and process refinement.

Location-Based Expansion: For multi-facility manufacturers, location-based rollout allows for localized customization while maintaining corporate procurement standards and integration requirements.

Change Management and Training

User Adoption Strategies: Comprehensive training programs, user-friendly interfaces, and clear value proposition communication ensure procurement teams embrace rather than resist automation technology.

Process Documentation: Updated standard operating procedures and workflow documentation provide ongoing reference materials and support consistent implementation across the organization.

Continuous Improvement Framework: Regular system performance reviews and user feedback collection enable ongoing optimization and feature enhancement that maximizes automation value.

Hyperbots: Leading AI Co-pilots for Manufacturing Procurement

Hyperbots has established itself as the premier provider of AI-powered procurement automation solutions specifically designed for manufacturing environments. The platform's comprehensive suite of AI Co-pilots delivers unmatched capabilities for factory procurement automation while integrating seamlessly with existing manufacturing systems.

Hyperbots Procurement Copilot: Core Capabilities

The Hyperbots Procurement Copilot represents the most advanced manufacturing purchase order automation solution available in 2025. This AI-powered platform shrinks procurement cycle times from request to purchase order while delivering instant ERP-synced approvals and providing finance teams with real-time spend visibility for compliant, cost-effective purchasing.

Intelligent Purchase Request Processing: Advanced machine learning algorithms analyze purchase requisitions in context of manufacturing schedules, inventory levels, and supplier performance to optimize procurement decisions automatically.

Dynamic Approval Orchestration: Smart routing capabilities consider organizational hierarchy, budget thresholds, and urgency factors to ensure appropriate oversight without creating bottlenecks in time-sensitive manufacturing environments.

Real-Time ERP Integration: Seamless synchronization with leading ERP platforms including SAP, Oracle, NetSuite, and Microsoft Dynamics ensures purchase orders immediately impact financial reporting and inventory management.

Compliance and Audit Trail Management: Automated documentation and approval tracking provide comprehensive audit trails that satisfy regulatory requirements while simplifying compliance management.

Comprehensive AI Co-pilot Ecosystem

Hyperbots extends beyond standalone purchase order automation to provide end-to-end procure-to-pay automation through integrated AI Co-pilots:

Invoice Processing Co-pilot: Automated invoice capture, validation, and processing that integrates seamlessly with purchase order data to enable three-way matching and streamlined payment processing.

Vendor Management Co-pilot: Comprehensive supplier relationship management that includes performance monitoring, risk assessment, and contract compliance tracking specifically tailored for manufacturing supply chains.

Payment Co-pilot: Intelligent payment timing optimization that balances cash flow management with early payment discount capture while maintaining supplier relationship quality.

Transformational Impact of Hyperbots Platform Capabilities

The implementation of Hyperbots AI Co-pilots creates transformational changes across manufacturing procurement operations, delivering measurable improvements in efficiency, accuracy, and cost management that extend far beyond traditional automation benefits.

Operational Transformation Metrics

Cycle Time Optimization: Hyperbots customers typically experience reduction in purchase order cycle times, with routine procurement requests processed in minutes rather than days. This acceleration enables manufacturers to respond rapidly to production changes and market opportunities.

Process Accuracy Enhancement: AI-powered validation and cross-referencing eliminate virtually all manual data entry errors, achieving 99.8% accuracy rates in purchase order generation and processing.

Productivity Multiplication: Manufacturing procurement teams using Hyperbots AI Co-pilots report productivity improvements, allowing staff to focus on strategic supplier relationships and value-added activities rather than routine transaction processing.

Financial Impact Realization

Direct Cost Reduction: Organizations implementing the complete Hyperbots platform achieve average operational cost reductions of 80% in procurement-related activities through elimination of manual processes and optimization of procurement decisions.

Working Capital Optimization: Intelligent payment timing and supplier term optimization typically improve cash flow while maintaining supplier relationship quality and capturing available early payment discounts.

Hidden Cost Elimination: Automated compliance monitoring and exception management eliminate costly audit findings, emergency procurement premiums, and supplier relationship issues that create hidden costs in traditional procurement operations.

Strategic Capability Development

Data-Driven Decision Making: Comprehensive analytics and reporting capabilities enable procurement teams to identify cost optimization opportunities, assess supplier performance trends, and make strategic sourcing decisions based on real-time data rather than historical reports.

Scalability Without Complexity: As manufacturing operations expand or acquire new facilities, Hyperbots AI Co-pilots scale seamlessly without proportional increases in administrative overhead, enabling profitable growth without procurement bottlenecks.

Supplier Partnership Enhancement: Automated communication, performance tracking, and issue resolution capabilities strengthen supplier relationships through improved transparency, faster response times, and collaborative problem-solving approaches.

ROI Analysis: Hyperbots-Led Improvements in Manufacturing Procurement

The return on investment from implementing Hyperbots AI Co-pilots in manufacturing environments consistently exceeds expectations across both tangible and intangible benefit categories. Comprehensive ROI analysis demonstrates compelling financial justification for automation investment.

Productivity and Efficiency Gains

Cycle Time Value: Reduction of procurement cycle times from days to hours enables manufacturers to respond more rapidly to production schedule changes, market opportunities, and customer requirements. This agility improvement is particularly valuable in make-to-order manufacturing environments.

Inventory Optimization: Better procurement timing and demand forecasting integration typically reduces inventory carrying costs while improving service levels to production operations.

Strategic Value Creation

Supplier Relationship Enhancement: Improved communication, performance tracking, and collaborative problem-solving capabilities enable stronger supplier partnerships that deliver long-term cost advantages and innovation opportunities.

Procurement Team Evolution: Elimination of routine transaction processing enables procurement professionals to focus on strategic activities including supplier development, market analysis, and cost optimization initiatives that create ongoing value.

Organizational Agility: Automated procurement processes enable manufacturers to scale operations, enter new markets, or adapt to changing conditions without procurement constraints or proportional increases in administrative complexity.

Investment Payback Timeline

Most manufacturing organizations achieve complete ROI payback within months of Hyperbots implementation, with benefits continuing to compound over time as AI capabilities improve and organizational procurement practices mature.

Industry-Specific Applications and Use Cases

Manufacturing purchase order automation delivers specialized benefits across different industrial segments, with Hyperbots AI Co-pilots providing tailored capabilities that address sector-specific procurement challenges and regulatory requirements.

Automotive Manufacturing

Automotive manufacturers face unique procurement complexity due to just-in-time production requirements, extensive supplier networks, and stringent quality standards. Hyperbots AI Co-pilots address these challenges through:

Sequential Delivery Optimization: Intelligent scheduling algorithms coordinate procurement timing with production line requirements, ensuring components arrive precisely when needed without creating inventory carrying cost burdens.

Supplier Quality Integration: Automated quality certification tracking and performance monitoring ensure all procurement decisions consider supplier quality history and certification status before purchase order generation.

Regulatory Compliance Management: Automated tracking of supplier certifications, environmental compliance, and safety standards ensures all procurement activities meet automotive industry regulatory requirements.

Electronics and Semiconductor Manufacturing

Electronics manufacturing requires precision in component procurement due to rapid technological change, supply chain volatility, and strict quality requirements:

Component Lifecycle Management: AI algorithms monitor component end-of-life announcements and automatically suggest alternative procurement strategies to avoid production disruptions.

Supply Chain Risk Monitoring: Real-time analysis of supplier financial stability, geopolitical risks, and capacity constraints enables proactive procurement decisions that maintain production continuity.

Quality and Traceability Requirements: Comprehensive documentation and traceability capabilities ensure compliance with electronics industry quality standards and regulatory requirements.

Pharmaceutical and Medical Device Manufacturing

Highly regulated pharmaceutical and medical device manufacturing environments require specialized procurement capabilities:

FDA Compliance Integration: Automated supplier qualification tracking and documentation management ensure all procurement activities comply with FDA regulations and validation requirements.

Change Control Management: Integration with quality management systems ensures procurement changes follow appropriate change control procedures and maintain manufacturing compliance status.

Batch Record Integration: Connection with manufacturing execution systems enables procurement decisions that support batch record requirements and product traceability obligations.

Food and Beverage Manufacturing

Food and beverage manufacturers face unique procurement challenges related to ingredient safety, regulatory compliance, and supply chain transparency:

Ingredient Traceability: Comprehensive lot tracking and supplier documentation management support food safety requirements and regulatory compliance obligations.

Shelf Life Optimization: Intelligent procurement timing considers ingredient shelf life, production schedules, and inventory rotation requirements to minimize waste while maintaining production capability.

Supplier Certification Management: Automated tracking of supplier food safety certifications, organic status, and quality approvals ensures compliance with industry standards and customer requirements.

Integration with Manufacturing Systems

Successful factory procurement automation requires seamless integration with existing manufacturing systems to ensure data consistency, process alignment, and operational efficiency. Hyperbots AI Co-pilots provide comprehensive integration capabilities across the manufacturing technology stack.

Enterprise Resource Planning (ERP) Integration

Real-Time Data Synchronization: Bidirectional integration with leading ERP platforms including SAP, Oracle, NetSuite, and Microsoft Dynamics ensures purchase orders immediately impact financial reporting, inventory management, and production planning systems.

Chart of Accounts Alignment: Automated GL coding ensures purchase orders align with organizational accounting structures while maintaining consistency across multiple manufacturing locations.

Budget Integration: Real-time budget checking against departmental allocations, project codes, and capital expenditure plans prevents overruns while maintaining operational flexibility for critical procurement decisions.

Manufacturing Execution System (MES) Connectivity

Production Schedule Alignment: Integration with MES platforms enables procurement timing optimization based on actual production schedules rather than theoretical planning data, improving inventory turnover while maintaining production continuity.

Work Order Integration: Direct connectivity with manufacturing work orders enables automatic generation of procurement requests for job-specific materials, components, and tooling requirements.

Quality Data Integration: Connection with quality management modules ensures procurement decisions consider supplier quality history and performance metrics in real-time decision-making processes.

Supply Chain Management System Integration

Demand Planning Connectivity: Integration with demand planning systems enables procurement decisions that consider forecasted requirements, seasonal variations, and market trends rather than historical consumption patterns alone.

Inventory Optimization: Real-time inventory level monitoring across multiple locations enables optimized procurement decisions that balance carrying costs with stockout risks while considering supplier lead times and minimum order quantities.

Supplier Portal Integration: Direct connectivity with supplier systems enables electronic order transmission, acknowledgment, and status updates that eliminate manual communication overhead while maintaining comprehensive audit trails.

Quality Management System Integration

Supplier Qualification Tracking: Automated monitoring of supplier certifications, quality performance, and compliance status ensures procurement decisions align with quality requirements and regulatory obligations.

Inspection and Testing Integration: Connection with incoming inspection systems provides feedback loops that inform future procurement decisions based on actual supplier performance rather than historical data alone.

Corrective Action Integration: Integration with supplier corrective action tracking systems ensures procurement decisions consider ongoing quality issues and supplier improvement initiatives.

Implementation Best Practices and Success Factors

Achieving maximum value from manufacturing purchase order automation requires adherence to proven implementation methodologies that minimize disruption while accelerating user adoption and system optimization.

Strategic Planning and Preparation

Executive Sponsorship: Successful implementations require strong leadership commitment and clear communication of strategic objectives to ensure organization-wide support for change management initiatives.

Cross-Functional Team Formation: Implementation teams should include representatives from procurement, manufacturing operations, finance, IT, and key supplier organizations to ensure all stakeholder requirements are addressed comprehensively.

Process Optimization Before Automation: Rather than simply automating existing inefficient processes, leading organizations first optimize workflows to eliminate unnecessary steps, reduce approval complexity, and standardize procedures across manufacturing locations.

Technology Architecture Considerations

Integration Strategy Development: Comprehensive mapping of existing systems, data flows, and integration requirements ensures seamless connectivity between procurement automation and manufacturing systems without creating data silos or process bottlenecks.

Security and Compliance Framework: Implementation of appropriate cybersecurity measures, access controls, and audit trail capabilities ensures procurement automation meets organizational security requirements and regulatory compliance obligations.

Scalability Planning: Architecture decisions should consider future growth, additional manufacturing locations, and evolving business requirements to avoid costly system replacements or major modifications.

User Adoption and Change Management

Training Program Development: Comprehensive training programs that address both system functionality and process changes ensure users can effectively leverage automation capabilities while maintaining compliance with organizational procedures.

Communication Strategy: Clear, consistent communication about implementation timeline, expected benefits, and role changes helps manage user expectations and reduce resistance to process automation initiatives.

Success Metrics Definition: Establishment of clear, measurable success criteria enables ongoing monitoring of implementation progress and identification of areas requiring additional focus or support.

Continuous Improvement Framework

Performance Monitoring: Regular assessment of system performance, user satisfaction, and business impact enables identification of optimization opportunities and validation of expected benefits realization.

Process Refinement: Ongoing analysis of procurement patterns, exception handling, and approval workflows supports continuous optimization of automation rules and decision-making algorithms.

Supplier Feedback Integration: Regular collection and analysis of supplier feedback regarding automated processes enables identification of improvements that benefit both internal operations and supplier relationships.

Future Trends in Manufacturing Procurement Automation

The evolution of manufacturing purchase order automation continues to accelerate, with emerging technologies and changing market conditions creating new opportunities for operational improvement and competitive advantage.

Artificial Intelligence and Machine Learning Advancement

Predictive Procurement Analytics: Advanced AI algorithms will increasingly predict procurement needs based on production forecasts, market conditions, and historical consumption patterns, enabling proactive rather than reactive procurement strategies.

Autonomous Decision Making: Agentic AI capabilities will expand to enable autonomous procurement decisions within defined parameters, reducing human intervention requirements while maintaining appropriate oversight and control.

Natural Language Processing Enhancement: Improved natural language processing will enable more sophisticated analysis of supplier communications, contract terms, and market intelligence to inform procurement optimization strategies.

Supply Chain Intelligence Integration

Real-Time Market Data Integration: Integration with commodity pricing feeds, supply chain disruption monitoring, and geopolitical risk assessment systems will enable more informed procurement timing and sourcing decisions.

Supplier Network Analysis: Advanced analytics will provide deeper insights into supplier relationships, dependencies, and risk factors to optimize supplier portfolio management and reduce supply chain vulnerabilities.

Sustainability and ESG Integration: Environmental, social, and governance (ESG) criteria will become increasingly integrated into procurement decision-making algorithms, supporting organizational sustainability objectives while maintaining cost and quality requirements.

Technology Platform Evolution

Blockchain Integration: Blockchain technology will enhance supply chain transparency, contract management, and payment processing while providing immutable audit trails that support regulatory compliance and dispute resolution.

Internet of Things (IoT) Connectivity: Integration with IoT sensors and smart manufacturing equipment will enable automatic procurement triggering based on actual equipment condition, consumption rates, and maintenance requirements.

Cloud-Native Architecture: Continued evolution toward cloud-native platforms will provide enhanced scalability, security, and integration capabilities while reducing total cost of ownership and implementation complexity.

Regulatory and Compliance Evolution

Automated Regulatory Monitoring: Advanced compliance monitoring capabilities will automatically track changing regulatory requirements and adjust procurement processes to maintain compliance without manual intervention.

Global Trade Automation: Enhanced integration with customs systems, trade compliance databases, and international shipping platforms will streamline global procurement while ensuring compliance with evolving trade regulations.

Data Privacy and Security Enhancement: Continued advancement in cybersecurity technologies and privacy protection capabilities will enable secure automation of sensitive procurement data while meeting evolving regulatory requirements.

Choosing the Right Manufacturing PO Automation Solution

Selecting an optimal factory procurement automation platform requires careful evaluation of organizational requirements, system capabilities, and long-term strategic objectives. The decision significantly impacts operational efficiency and competitive positioning.

Critical Evaluation Criteria

Manufacturing-Specific Functionality: Solutions should demonstrate deep understanding of manufacturing procurement requirements including BOM management, production schedule integration, regulatory compliance, and supplier quality management rather than generic procurement capabilities.

Integration Capabilities: Comprehensive evaluation of ERP integration, MES connectivity, and supplier portal compatibility ensures seamless data flow and process alignment across the manufacturing technology stack.

Scalability and Flexibility: Platform architecture should support organizational growth, additional manufacturing locations, and evolving business requirements without requiring costly system replacements or major customizations.

AI and Automation Sophistication: Assessment of artificial intelligence capabilities, machine learning algorithms, and autonomous decision-making features determines the platform's ability to deliver ongoing optimization and adaptation to changing conditions.

Vendor Assessment Framework

Manufacturing Industry Experience: Vendors should demonstrate extensive experience with manufacturing procurement challenges, regulatory requirements, and integration complexity rather than general procurement automation expertise.

Reference Customer Validation: Direct engagement with reference customers in similar manufacturing segments provides realistic assessment of implementation experience, benefits realization, and ongoing support quality.

Technology Roadmap Alignment: Vendor technology development plans should align with organizational strategic objectives and emerging industry trends to ensure long-term platform viability and capability enhancement.

Implementation and Support Capabilities: Assessment of vendor implementation methodology, training programs, and ongoing support capabilities determines the likelihood of successful deployment and user adoption.

Total Cost of Ownership Analysis

Implementation Investment: Comprehensive analysis of software licensing, professional services, integration development, and training costs provides realistic assessment of initial investment requirements.

Ongoing Operating Costs: Evaluation of subscription fees, maintenance costs, and internal resource requirements enables accurate projection of total cost of ownership over the platform lifecycle.

Benefits Quantification: Realistic assessment of expected cost savings, productivity improvements, and strategic value creation enables accurate ROI calculation and investment justification.

Risk Assessment: Identification of implementation risks, vendor viability concerns, and technology obsolescence factors supports informed decision-making and risk mitigation planning.

Getting Started with Manufacturing Procurement Automation

Organizations ready to transform their factory procurement operations through automation should follow a structured approach that maximizes success probability while minimizing implementation risks and operational disruption.

Initial Assessment and Planning

Current State Analysis: Comprehensive evaluation of existing procurement processes, system landscape, and performance metrics provides baseline understanding and optimization opportunity identification.

Stakeholder Engagement: Early engagement with procurement teams, manufacturing operations, finance departments, and key suppliers ensures comprehensive requirements gathering and change management planning.

Business Case Development: Quantification of expected benefits, investment requirements, and implementation timeline supports executive approval and resource allocation decisions.

Success Criteria Definition: Clear establishment of measurable success metrics enables objective assessment of implementation progress and benefits realization validation.

Vendor Selection and Procurement

Requirements Documentation: Detailed specification of functional, technical, and integration requirements ensures vendor proposals address organizational needs comprehensively.

Solution Demonstration: Hands-on evaluation of vendor platforms using realistic manufacturing scenarios provides accurate assessment of system capabilities and user experience quality.

Reference Validation: Direct engagement with vendor reference customers provides realistic insight into implementation experience, benefits realization, and ongoing satisfaction levels.

Contract Negotiation: Comprehensive agreement terms covering implementation scope, success criteria, support requirements, and performance guarantees protect organizational interests while ensuring vendor accountability.

Implementation Execution

Project Team Formation: Cross-functional implementation teams with appropriate skills, authority, and time commitment ensure comprehensive project execution and stakeholder representation.

Phased Deployment Planning: Sequential implementation across procurement categories, manufacturing locations, or organizational units enables focused change management while validating system performance.

Training and Support: Comprehensive training programs covering system functionality, process changes, and ongoing support resources ensure successful user adoption and capability utilization.

Performance Monitoring: Regular assessment of implementation progress, system performance, and user satisfaction enables early identification of issues and optimization opportunities.

Experience the Future of Manufacturing Procurement

Manufacturing organizations ready to achieve transformational improvements in procurement efficiency, cost management, and supplier relationships can begin their automation journey with Hyperbots' comprehensive AI Co-pilot platform.

The convergence of artificial intelligence, cloud computing, and manufacturing domain expertise has created unprecedented opportunities for operational excellence and competitive advantage. Organizations that embrace intelligent automation today position themselves for sustained success in increasingly competitive global markets.

Hyperbots' proven track record of delivering 80% operational cost reductions while improving procurement accuracy and supplier relationships demonstrates the transformational potential of purpose-built manufacturing automation solutions. The platform's comprehensive integration capabilities, industry-specific intelligence, and outcome-focused optimization create lasting value that extends far beyond traditional procurement automation benefits.

Leading manufacturers worldwide have already experienced the competitive advantages of AI-powered procurement automation. Those who delay implementation risk falling behind in operational efficiency, cost competitiveness, and supplier relationship quality while competitors gain sustainable advantages through intelligent automation.

To explore how Hyperbots AI Co-pilots can transform your manufacturing procurement operations, visit our Purchase Order Automation page or schedule a personalized demonstration to see the platform's capabilities applied to your specific manufacturing environment and requirements.

Frequently Asked Questions

Q1: What is the typical implementation timeline for manufacturing purchase order automation?

A: Most manufacturing organizations complete Hyperbots implementation within weeks, depending on system complexity and integration requirements. The phased deployment approach enables immediate benefits realization while minimizing operational disruption.

Q2: How does AI-powered procurement automation integrate with existing ERP systems?

A: Hyperbots AI Co-pilots provide real-time bidirectional integration with leading ERP platforms including SAP, Oracle, NetSuite, and Microsoft Dynamics through standard APIs and custom integration development as needed.

Q3: What level of procurement staff reduction can be expected with full automation?

A: Organizations typically reduce procurement administrative workload by 60-80% while improving service levels, enabling staff redeployment to strategic activities like supplier relationship management and cost optimization initiatives.

Q4: How does manufacturing purchase order automation handle complex approval workflows?

A: AI-powered approval routing considers organizational hierarchy, budget thresholds, procurement categories, and urgency factors to optimize approval paths while maintaining appropriate oversight and compliance requirements.

Q5: What cybersecurity measures protect automated procurement processes?

A: Hyperbots employs enterprise-grade security including end-to-end encryption, multi-factor authentication, role-based access controls, and comprehensive audit trails. The platform maintains SOC 2 Type II compliance and integrates with organizational security frameworks.

Q6: Can manufacturing purchase order automation handle emergency procurement situations?

A: Yes, AI algorithms automatically identify urgent procurement requests and expedite processing through optimized approval routes while maintaining compliance requirements. Emergency procurement workflows can process critical orders in minutes rather than hours or days.

Q7: How does the platform handle multi-location manufacturing operations?

A: Hyperbots supports centralized policy management with location-specific customization, enabling consistent procurement standards while accommodating local operational requirements, supplier relationships, and regulatory compliance needs.

Q8: What supplier onboarding and management capabilities are included?

A: The platform includes comprehensive supplier qualification tracking, performance monitoring, risk assessment, and automated communication capabilities that streamline supplier relationships while maintaining compliance with organizational and regulatory requirements.

Q9: How does procurement automation impact supplier relationships?

A: Automation typically strengthens supplier relationships through improved communication consistency, faster response times, accurate order processing, and transparent performance tracking that enables collaborative improvement initiatives.

Q10: What training and support resources are provided during implementation?

A: Hyperbots provides comprehensive training programs, implementation support, documentation resources, and ongoing customer success management to ensure successful adoption and optimization of procurement automation capabilities.