The Ultimate Guide to Purchase Orders: Process, Templates, and Best Practices

Your Complete Roadmap to Flawless Procurement: Understanding the PO Process, Utilizing Essential Templates, and Implementing Industry Best Practices.

Introduction

In today's business landscape, purchase orders (POs) serve as the backbone of transparent, accountable procurement operations. Yet despite their critical importance, many organizations struggle with manual PO processes, inconsistent templates, and approval bottlenecks that slow down procurement cycles and increase compliance risks.

This comprehensive guide addresses the full spectrum of purchase order management, from fundamental concepts to advanced automation strategies. Whether you're a finance professional seeking to streamline your accounts payable workflow, a procurement manager looking to enforce better controls, a small-to-medium business owner building scalable purchasing processes, or an ERP user wanting to maximize your system's PO capabilities, this resource provides actionable insights for every stage of your journey.

What This Guide Covers:

Core definitions and distinctions between POs, invoices, and requisitions

The complete purchase order lifecycle from requisition to payment

Step-by-step instructions for creating and issuing purchase orders

Standardized templates and document formats

Best practices for approval workflows, compliance, and recordkeeping

Solutions to common challenges through automation and AI-powered tools

Modern procurement demands more than basic documentation. Organizations that master purchase order management gain real-time visibility into spending, enforce budget controls, strengthen supplier relationships, and create audit-ready paper trails. With the right processes and purchase order automation software, companies achieve 80% faster cycle times and near-perfect accuracy in three-way matching.

Let's begin by establishing the foundational understanding of what purchase orders are and why they matter.

What Is a Purchase Order (PO) in Business?

Basic Definition and Purpose

A purchase order is a legally binding commercial document issued by a buyer to a seller, authorizing a transaction before goods or services are delivered. Understanding what a PO is in business begins with recognizing its dual role: it's both a control mechanism for the buyer and a commitment document for the seller.

Key characteristics of a purchase order:

Authorization instrument: Represents formal approval to proceed with a purchase

Legal contract: Creates binding obligations once accepted by the supplier

Budget control tool: Locks spending against approved budgets or cost centers

Audit documentation: Provides traceable evidence of purchasing decisions

Communication vehicle: Clearly specifies quantities, prices, delivery terms, and payment conditions

From an accounting perspective, purchase orders play a crucial role in accrual-based financial management. When a PO is issued, many ERP systems create an encumbrance or commitment in the general ledger, reserving funds against the budget without yet recording an actual expense. This prevents overspending and gives finance teams real-time visibility into both actual and committed expenditures.

The PO vs. Invoice Distinction:

One of the most common points of confusion in procurement is distinguishing purchase orders from invoices. While both are critical procurement documents, they serve opposite functions:

Aspect | Purchase Order | Invoice |

Issuer | Buyer creates and sends to seller | Seller creates and sends to buyer |

Timing | Before goods/services are delivered | After goods/services are delivered |

Purpose | Authorizes the purchase | Requests payment |

Legal Status | Creates contractual obligation | Fulfills contractual obligation |

Accounting Impact | Creates commitment/encumbrance | Records actual expense and liability |

Understanding this distinction is essential for proper invoice processing and three-way matching, where purchase orders, receiving documents, and invoices must align before payment approval.

Types of Purchase Orders

Not all purchase orders follow the same structure. Organizations use different PO types depending on the nature of their purchasing needs, supplier relationships, and the predictability of requirements. Understanding what constitutes a standard purchase order and its variations helps organizations choose the right approach for each scenario.

1. Standard Purchase Order

The most common type, used for one-time purchases with clearly defined specifications:

Specific quantities and line items

Fixed pricing

Defined delivery date

Single transaction

Complete specification at time of issuance

Use cases: Equipment purchases, specific project materials, one-time service engagements

2. Blanket Purchase Order

An agreement for multiple purchases over a period, typically used when:

Quantities are uncertain but expected to be ongoing

Pricing is negotiated upfront

Items are standard and regularly needed

Administrative efficiency is prioritized over per-transaction control

Example: A manufacturing company establishes a blanket PO with an office supply vendor for $50,000 over 12 months. Individual releases against this blanket order don't require new approvals, streamlining the procurement process while maintaining spending limits.

3. Contract Purchase Order

Used for long-term relationships where terms are established but specific delivery schedules may vary:

Extended timeframe (often multi-year)

Detailed terms and conditions

May include service level agreements (SLAs)

Pricing framework with potential adjustment clauses

Requires periodic review and renewal

Use cases: Enterprise software subscriptions, facility maintenance contracts, professional services retainers

4. Planned Purchase Order

Similar to blanket POs but with more structure around delivery schedules:

Specified delivery dates or milestones

Quantities defined per period

Used in production planning scenarios

Enables better inventory management

Supplier receives advance notice of requirements

Use cases: Manufacturing components with just-in-time delivery, seasonal inventory builds, construction projects with phased material needs

Selecting the appropriate PO type impacts both operational efficiency and financial controls. Organizations with mature procurement processes typically maintain policies defining which type applies to different spending categories, approval authorities, and supplier relationships.

How Does a Purchase Order Work?

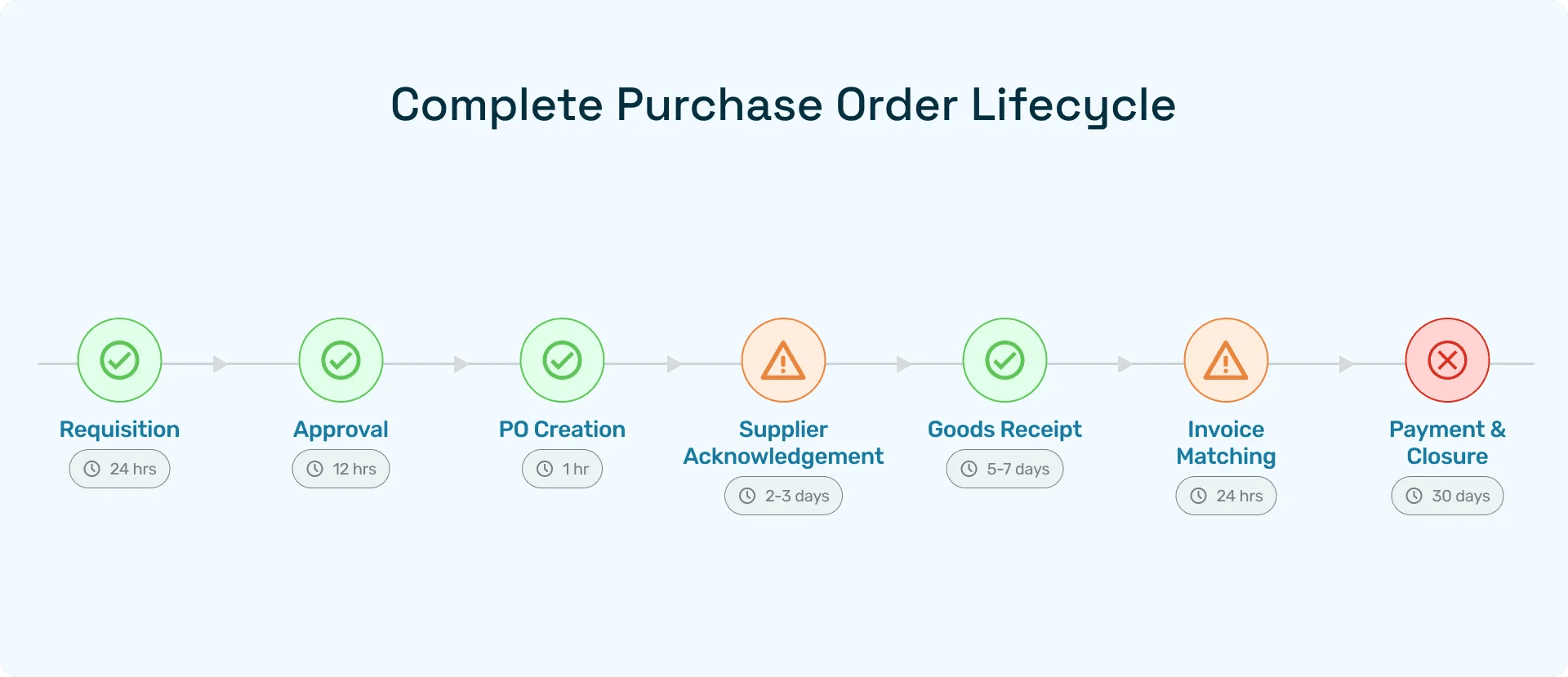

The Purchase Order Lifecycle

Understanding how a purchase order works requires following the complete lifecycle from initial need identification through final payment. This end-to-end process typically consists of seven key stages:

Stage 1: Requisition

The lifecycle begins when an employee or department identifies a purchasing need and creates a purchase requisition (PR). This internal document:

Describes what needs to be purchased and why

Estimates cost and specifies budget code

Identifies preferred supplier (if known)

Includes approval from department manager or budget owner

The distinction between purchase requisitions and purchase orders is critical: requisitions are internal requests for permission to buy, while POs are external commitments to suppliers.

Stage 2: Approval

Once submitted, the requisition enters an approval workflow based on:

Dollar amount thresholds

Department and cost center

Type of goods or services

Supplier risk profile

Budget availability

Modern organizations leverage automated approval workflows that route requisitions based on configurable rules, dramatically reducing cycle times from days to hours or minutes.

Stage 3: PO Creation and Issuance

After approval, procurement converts the requisition into a formal purchase order. The purchase order creation process involves:

Assigning a unique PO number for tracking

Verifying supplier information and delivery address

Confirming line items, quantities, and prices

Including terms, conditions, and delivery requirements

Obtaining final authorization signature or digital approval

Issuing the purchase order to the supplier can happen through multiple channels: email, EDI transmission, supplier portal upload, or integration with supplier systems.

Stage 4: Supplier Acknowledgment

Professional suppliers confirm receipt and acceptance of the PO, indicating:

Ability to fulfill the order as specified

Confirmation of pricing and terms

Expected delivery date

Any exceptions or required modifications

This acknowledgment transforms the PO from a proposal into a binding contract.

Stage 5: Goods Receipt / Service Completion

When items arrive or services are rendered:

Receiving department inspects and confirms quantity and quality

Goods Receipt Note (GRN) or service completion certificate is created

Variances are documented (shortages, damages, quality issues)

ERP system updates inventory and PO status

Stage 6: Invoice Matching

The supplier sends an invoice requesting payment. Automated invoice processing systems perform three-way matching:

Document | Key Data Points Compared |

Purchase Order | Authorized quantities, prices, terms |

Goods Receipt | Actual quantities received, condition |

Invoice | Billed quantities, prices, amounts |

Discrepancies trigger exception workflows for investigation and resolution. Organizations implementing AI-driven matching strategies achieve 95%+ straight-through processing rates.

Stage 7: Payment Authorization and PO Closure

Once matching is successful:

Invoice is approved for payment

Payment is scheduled according to terms (net 30, net 60, etc.)

Payment execution occurs via ACH, check, or virtual card

Purchase order is marked as completed and closed

Closed POs remain in the system as part of the permanent procurement record but no longer encumber budgets or appear on open PO reports.

POs in the Business Ecosystem

Purchase orders don't exist in isolation - they're interconnected with virtually every business function and system. Understanding these relationships is crucial for designing effective procurement processes.

Procurement's Role:

Sources suppliers and negotiates terms

Establishes preferred vendor lists and contracts

Manages supplier relationships and performance

Ensures competitive pricing and quality standards

Maintains compliance with purchasing policies

Modern vendor management systems track supplier performance metrics, contract terms, and risk factors that influence PO creation and approval thresholds.

Finance and Accounting Integration:

Validates budget availability before PO approval

Creates accruals for received but not yet invoiced goods

Reconciles PO commitments with actual spending

Manages cash flow forecasting based on PO pipeline

Ensures proper GL coding and cost allocation

The integration between purchase orders and GL coding structures determines how spending is categorized, reported, and analyzed.

Operations and Inventory:

Triggers inventory replenishment based on stock levels

Coordinates delivery timing with production schedules

Manages receiving and quality inspection

Updates inventory systems upon goods receipt

Coordinates with warehouse operations

Sales and Customer Success:

Understanding how POs fit into the sales cycle is equally important. From the supplier's perspective, customer POs:

Trigger order fulfillment workflows

Establish legally binding terms of sale

Define delivery and invoicing requirements

Form the basis for revenue recognition

Create obligations for performance and quality

Real-World Application Examples:

B2B Scenario: A manufacturing company receives a $150,000 PO from an automotive client for custom components. The PO specifies:

Exact part numbers and specifications

Delivery schedule aligned with production

Quality inspection requirements

Payment terms: net 45 days

Penalties for late delivery or quality issues

This PO drives production scheduling, materials procurement, quality assurance protocols, and revenue forecasting.

B2C Scenario: While less common in direct consumer transactions, POs appear in:

Government agencies purchasing from businesses

Large construction projects with homeowners

Commercial services (catering, event planning)

Custom manufacturing for individual clients

The formality of the PO process scales with transaction size, complexity, and the need for documentation and control.

How to Make a Purchase Order (Step-by-Step)

Key Steps to Create a Purchase Order

Creating an effective purchase order requires attention to detail and adherence to organizational standards. Learning how to make a purchase order begins with understanding the essential information that must be included and validated.

Step 1: Gather Essential Information

Before creating a PO, collect:

Supplier Information:

Legal business name and tax ID

Billing address

Shipping/delivery address (if different)

Primary contact name, email, and phone

Remittance details for payment

Internal Information:

Requesting department and cost center

Budget code or project number

Delivery location and receiving contact

Approver names and authorization levels

Transaction Details:

Complete item descriptions or service specifications

Quantities needed

Unit prices and currency

Delivery date or service completion timeline

Payment terms (net 30, 2/10 net 30, etc.)

Shipping method and cost

Any special instructions or requirements

Step 2: Assign PO Number

Every purchase order requires a unique identifier for tracking and reference. Organizations typically use:

Sequential numbering (PO-2025-0001, PO-2025-0002)

Department-specific prefixes (MKT-2025-0145, IT-2025-0089)

Project-based coding for better cost tracking

Date-based formats for easier filing

Modern purchase order automation platforms auto-generate PO numbers, eliminating duplication risks and ensuring consistent formatting.

Step 3: Specify Line Items with Precision

Each line item should include:

Field | Description | Example |

Line # | Sequential identifier | 1, 2, 3... |

Item Code | SKU or service code | COMP-2024-X15 |

Description | Clear, unambiguous specification | Dell Latitude 5540 Laptop, 16GB RAM, 512GB SSD |

Quantity | Number of units | 25 |

Unit of Measure | Standard measurement | Each (EA), hours (HR), cases (CS) |

Unit Price | Cost per unit | $1,299.00 |

Line Total | Quantity × Unit Price | $32,475.00 |

GL Code | Accounting classification | 5200-IT-Hardware |

Delivery Date | Required arrival date | 2025-11-15 |

Clear item descriptions prevent confusion, reduce errors, and facilitate accurate receiving and invoice matching.

Step 4: Define Terms and Conditions

Standard terms to include:

Payment Terms: When payment is due (net 30, net 60, 2/10 net 30)

Delivery Terms: FOB point, shipping responsibility, insurance

Warranties: Product warranties or service guarantees

Returns Policy: Conditions for returns or exchanges

Quality Standards: Specifications or inspection requirements

Compliance Requirements: Regulatory or certification needs

Organizations should maintain standardized terms templates that automatically populate based on supplier relationship and transaction type.

Step 5: Include Tax Information

Proper sales tax verification is critical:

Verify applicable tax jurisdictions based on delivery location

Apply correct tax rates to taxable items

Identify tax-exempt items or transactions

Include tax exemption certificates when applicable

Calculate and display tax separately on the PO

Errors in tax calculation create downstream problems in invoice matching and can result in compliance issues or overpayments.

Step 6: Add Approval Signatures

Depending on organizational policies:

Single approver for low-value POs

Multiple approvers for larger amounts or specific categories

Budget owner approval for department spending

Procurement approval for supplier and terms validation

Executive approval above threshold amounts

Digital approval workflows dramatically accelerate this step while maintaining proper controls and audit trails.

Step 7: Review for Accuracy

Before issuing, verify:

All fields are complete and accurate

Mathematical calculations are correct

Supplier information matches master data

Terms align with contracts or standard agreements

Budget availability is confirmed

Delivery dates are realistic and coordinated

A thorough review prevents costly errors, supplier confusion, and processing delays.

Purchase Order Creation in Practice

Understanding the theoretical steps is valuable, but practical implementation varies based on tools and organizational sophistication.

Common Tools for PO Creation:

Excel-Based Systems:

Simple template with formulas for calculations

Suitable for very small businesses with low volumes

Limited automation and control

Manual tracking and filing required

High risk of errors and version control issues

For organizations starting from scratch, creating purchase orders in Excel can work initially, but scalability and control limitations quickly become apparent.

Accounting Software:

QuickBooks, Xero, Sage, FreshBooks

Integrated with financial systems

Basic approval workflows

Standard templates and reporting

Limited customization for complex requirements

ERP Systems:

SAP, Oracle NetSuite, Microsoft Dynamics, Sage Intacct

Full procurement-to-pay integration

Advanced approval routing and controls

Multi-entity and multi-currency support

Comprehensive reporting and analytics

Organizations using NetSuite or Microsoft Dynamics benefit from tight integration between requisitions, POs, receiving, and invoice processing.

Specialized Procurement Platforms:

Coupa, Ariba, Procurify, Tipalti

Purpose-built for procurement workflows

Supplier collaboration portals

Advanced analytics and spend visibility

Can integrate with existing ERP systems

AI-Powered Automation:

The newest category, represented by platforms like Hyperbots' Procurement Co-Pilot, leverages artificial intelligence to:

Auto-extract information from requisitions and emails

Pre-populate PO fields based on historical data

Suggest suppliers and terms based on spend patterns

Intelligently route for approvals

Flag anomalies or policy violations

Continuously learn and improve from user corrections

Example Workflow: From Requisition to Issued PO

Day 1, 9:00 AM: Marketing manager emails procurement: "Need 50 branded backpacks for conference, budget $2,000, needed by Oct 30"

Day 1, 9:15 AM: AI assistant extracts key information and creates draft PR:

Item: Branded backpacks with logo

Quantity: 50

Budget: $2,000 ($40/unit)

Delivery: Oct 30, 2025

Cost Center: Marketing-Events

Day 1, 10:00 AM: System routes to marketing director for budget approval based on threshold rules

Day 1, 2:30 PM: Approved; automatically routed to procurement for supplier selection

Day 1, 3:45 PM: Procurement selects preferred supplier from master list, system pre-populates supplier details and standard terms

Day 1, 4:00 PM: PO created with auto-assigned number PO-2025-1847, reviewed, and issued electronically to supplier

Day 1, 4:15 PM: Supplier receives PO via email and portal notification, confirms acceptance and Oct 28 delivery

Total time: Same day vs. 3-5 days in manual processes

This acceleration comes from eliminating handoffs, automating data entry, and leveraging intelligent routing benefits clearly demonstrated in purchase order process automation case studies.

How to Issue a Purchase Order

Issuing POs to Suppliers

Creating a purchase order is only half the equation, effective issuance ensures suppliers receive, understand, and acknowledge orders promptly. Best practices for issuing purchase orders focus on clarity, speed, and confirmation.

Digital Issuance Methods:

Email Transmission:

Most common method for small-to-medium businesses

PO sent as PDF attachment

Subject line includes PO number for easy tracking

Body text highlights key details and delivery date

Request explicit acknowledgment from supplier

Pros: Universal, simple, creates automatic documentation Cons: Manual tracking required, potential delivery/spam issues, no automated workflow

EDI (Electronic Data Interchange):

Standardized computer-to-computer document exchange

Common EDI transaction sets: 850 (Purchase Order), 855 (PO Acknowledgment)

Used extensively in retail, manufacturing, and logistics

Requires EDI capability on both sides

Pros: Highly automated, minimal errors, instant transmission Cons: Implementation complexity, limited to capable trading partners

Supplier Portals:

Web-based interfaces provided by procurement platforms

Suppliers log in to view, acknowledge, and manage orders

Enable real-time status updates and document sharing

Support messaging and collaboration

Pros: Visibility, self-service, document centralization Cons: Requires supplier onboarding and training

ERP-to-ERP Integration:

Direct system integration between buyer and supplier

Real-time order transmission and status synchronization

Typically for strategic, high-volume relationships

Requires technical integration investment

Pros: Maximum automation and accuracy Cons: High implementation cost, limited applicability

Best Practices for PO Issuance:

Issue Promptly After Approval: Delays between approval and issuance can cause:

Price changes

Availability issues

Confusion about order status

Delayed delivery

Use Consistent Formatting: Standardized PO document templates ensure:

Professional appearance

Easy comprehension by suppliers

Consistent information placement

Recognition and trust

Include Clear Contact Information: Specify:

Procurement contact for order questions

Receiving contact for delivery coordination

Accounts payable contact for invoice submission

Escalation contact for urgent issues

Highlight Critical Information: Draw attention to:

Urgent delivery requirements

Special handling instructions

Quality or certification requirements

Changed terms from previous orders

Confirm Receipt: Implement confirmation workflows:

Request acknowledgment within 24 hours

Follow up on non-acknowledgment

Track acknowledgment rates by supplier

Flag potential issues early

Supplier Confirmation and Acknowledgment

The purchase order lifecycle includes a critical but often overlooked step: formal supplier acknowledgment. This confirmation serves multiple purposes:

Legal Clarity: Acknowledgment transforms the PO from an offer into a binding contract, establishing mutual agreement on terms.

Operational Alignment: Confirmation ensures the supplier:

Can fulfill the order as specified

Commits to the delivery timeline

Accepts the pricing and payment terms

Understands special requirements

Early Exception Detection: Acknowledgment responses may reveal:

Availability issues requiring timeline adjustments

Pricing discrepancies needing resolution

Specification clarifications

Capability limitations

What Should Supplier Acknowledgment Include?

PO number reference

Acceptance or exception status

Confirmed delivery date (or alternative if needed)

Any changes to quantities, pricing, or terms

Expected invoice date and amount

Tracking or reference numbers

Managing Acknowledgment Workflows:

Organizations with mature procurement processes implement systematic acknowledgment tracking:

Auto-request acknowledgment when PO is issued

Set expected response timeframe (typically 24-48 hours)

Automatically escalate non-responses to procurement team

Flag exceptions for immediate buyer review

Update ERP with confirmed delivery dates for accurate forecasting

Modern supplier management platforms automate these workflows, providing real-time visibility into which orders have been confirmed and which require attention.

Handling Exceptions:

When suppliers cannot accept POs as-is:

Availability Issues: Item is back-ordered or discontinued

Action: Identify acceptable alternatives or adjust timeline

Documentation: Update PO with revised item or delivery date

Communication: Inform requestor of change

Pricing Discrepancies: PO price differs from current supplier pricing

Action: Verify contract terms or negotiate resolution

Documentation: Update PO if price change accepted, or cancel and re-source

Communication: Obtain approval for price variance if above threshold

Specification Questions: Supplier needs clarification

Action: Provide additional details or technical specifications

Documentation: Add clarifying notes to PO

Communication: Confirm supplier understanding before proceeding

Effective exception management prevents order delays and builds stronger supplier relationships through clear communication and collaborative problem-solving.

Key Purchase Order Documents and Formats

What a PO Includes

Purchase order documents must contain specific information to be legally valid, operationally useful, and audit-compliant. Understanding the anatomy of a complete PO helps ensure nothing critical is omitted.

Header Information:

Element | Purpose | Example |

PO Number | Unique identifier for tracking | PO-2025-18475 |

PO Date | Date order was created | October 9, 2025 |

Required By Date | When items must arrive | November 15, 2025 |

Buyer Company Name | Legal entity placing order | Acme Manufacturing Inc. |

Buyer Address | Legal and shipping address | 123 Industrial Pkwy, Chicago, IL 60601 |

Buyer Tax ID | Federal EIN or VAT number | 12-3456789 |

Supplier Information:

Legal business name

Remit-to address for payment

Ship-from address if different

Supplier contact name, email, phone

Supplier account number (if applicable)

Delivery Information:

Ship-to address (may differ from buyer address)

Receiving contact name and phone

Receiving hours and special instructions

Delivery method (standard, expedited, freight)

Packaging requirements

Line Item Details:

Each line item must specify:

Line Number: Sequential identifier (1, 2, 3...)

Item Code/SKU: Supplier's product identifier

Description: Clear, complete specification including:

Product name and model

Size, color, or configuration details

Technical specifications if relevant

Service details if applicable

Quantity: How many units

Unit of Measure: EA, HR, CS, LB, etc.

Unit Price: Cost per unit in specified currency

Line Total: Quantity × Unit Price

GL Code: Accounting classification

Tax Code: Applicable tax treatment

Delivery Date: When this line item is needed

Financial Summary:

Subtotal: Sum of all line totals

Shipping/Freight: Delivery charges

Handling Fees: Any additional charges

Subtotal Before Tax: Subtotal + freight + fees

Tax: Calculated based on applicable rates

Total PO Amount: Final payable amount

Terms and Conditions:

Payment Terms: Net 30, 2/10 Net 30, Due on Receipt, etc.

Delivery Terms: FOB Origin, FOB Destination, CIF, etc.

Warranty: Standard or extended warranty terms

Returns: Conditions for product returns

Insurance: Who bears risk during shipment

Late Delivery: Penalties or remedies

Quality Standards: Specifications or certifications required

Confidentiality: NDA terms if applicable

Approval Information:

Names and titles of approvers

Approval dates

Electronic signature or digital authorization

Budget authorization reference

Why Document Accuracy Matters:

Inaccurate purchase orders create cascading problems:

Receiving Issues: Wrong items delivered, confusion about what was ordered, unable to match delivery to PO

Invoice Matching Failures: Discrepancies between PO, receipt, and invoice trigger holds and delays

Payment Disputes: Suppliers dispute short payments due to PO errors

Budget Problems: Incorrect GL codes lead to wrong cost allocation and budget tracking

Audit Findings: Incomplete or inaccurate POs fail compliance checks

Supplier Relationship Strain: Frequent errors damage credibility and trust

Organizations using AI-powered PO validation catch errors before issuance, maintaining 99%+ accuracy rates and virtually eliminating matching exceptions.

Templates and Samples

Standardized templates are foundational to efficient, consistent purchase order creation. Organizations should maintain a library of templates for different scenarios rather than recreating documents from scratch.

Common PO Template Formats:

Excel Templates:

Simple, widely accessible

Formulas calculate totals and taxes

Can include dropdown lists for consistent data entry

Easy to customize

Requires manual numbering and filing

Free purchase order sample templates are available for immediate use

Word Templates:

Professional formatting

Good for service-oriented purchases

Easy to create PDF versions

Limited calculation capability

Best for one-off or unique purchases

PDF Forms:

Professional appearance

Fillable fields for digital completion

Universal viewing compatibility

Cannot perform calculations

Best for distribution to suppliers

Cloud-Based Templates:

Google Sheets/Docs, Microsoft 365

Real-time collaboration

Version control and history

Auto-save and backup

Accessible from anywhere

Template Customization Guidelines:

By Department:

IT: Include technical specifications, software licensing details, installation requirements

Marketing: Creative assets, brand compliance, usage rights, event details

Facilities: Site-specific requirements, safety compliance, access needs

HR: Service dates, candidate details, confidentiality requirements

By Purchase Type:

Goods/Products:

Detailed item specifications

Quality standards

Warranty information

Return policies

Services: Understanding how purchase orders for services differ is critical:

Scope of work description

Deliverables and milestones

Hourly rates or fixed fees

Not-to-exceed amounts

Service levels and response times

Acceptance criteria

By Supplier Relationship:

Preferred suppliers: Simplified terms, pre-negotiated pricing, streamlined approval

New suppliers: Enhanced due diligence, additional terms, probationary conditions

High-risk suppliers: Additional insurance requirements, performance bonds, enhanced oversight

Template Best Practices:

Include Clear Instructions: Add notes explaining how to complete each section

Use Data Validation: Implement dropdown lists and format restrictions

Auto-Calculate Where Possible: Formulas for totals, taxes, discounts

Version Control: Date templates and maintain revision history

Accessibility: Ensure templates work on various devices and platforms

Branding: Include company logo, colors, and standard legal language

Regulatory Compliance: Incorporate required terms for your industry

Company Purchase Orders and Templates

Company purchase order best practices extend beyond individual transactions to encompass organizational standards, compliance requirements, and scalable systems.

Enterprise-Grade PO Management:

Centralized Template Library:

Single source of truth for all PO templates

Version-controlled with change tracking

Access-controlled based on user roles

Regularly reviewed and updated

Compliance-validated

Standardized Numbering Conventions: Organizations should establish clear PO numbering schemes:

Sequential: PO-100001, PO-100002 (simple but limited information)

Year-Based: 2025-0001, 2025-0002 (enables annual reset)

Department-Specific: IT-2025-0045, MKT-2025-0123 (tracks by function)

Entity-Based: US01-2025-0456, UK02-2025-0789 (multi-entity organizations)

Hybrid: 2025-IT-CHI-0045 (year-department-location-sequence)

Compliance Requirements by Industry:

Different industries face unique regulatory requirements that must be reflected in PO documentation:

Healthcare:

HIPAA compliance for service providers with data access

FDA requirements for medical devices and supplies

Biocompatibility and sterilization certifications

Chain-of-custody documentation

Financial Services:

SOC 2 compliance for technology vendors

Background check requirements for contractors

Data security and encryption standards

Business continuity requirements

Manufacturing:

ISO 9001 quality management documentation

Material certifications and test reports

RoHS and REACH compliance for electronics

Country of origin documentation for customs

Government Contractors:

FAR/DFARS compliance requirements

Small business and diversity reporting

Buy American Act provisions

Security clearance requirements

Organizations should work with legal and compliance teams to ensure company purchase order templates incorporate all necessary provisions.

Audit-Ready Documentation:

Purchase orders form a critical component of audit trails. To ensure audit readiness:

Complete Information: Every required field populated

Clear Approvals: Documented authorization at appropriate levels

Timestamp Tracking: Date/time stamps for creation, approval, issuance

Change History: Log of any modifications post-issuance

Supporting Documentation: Link to requisition, quotes, contracts

Archival Compliance: Retention per regulatory and tax requirements

Modern purchase order automation systems maintain immutable audit logs that track every action, providing complete transparency for internal and external auditors.

Specialized Types of Purchase Orders

Product vs. Service POs

While the fundamental purpose remains the same, purchase orders for services require different structural elements and approval logic compared to product-based POs.

Key Differences:

Aspect | Product POs | Service POs |

Specifications | Part numbers, quantities, dimensions | Scope of work, deliverables, outcomes |

Measurement | Discrete units (each, case, pound) | Time-based (hours, days) or milestone-based |

Receipt | Physical delivery, inspection, inventory | Service completion, acceptance criteria |

Pricing | Per-unit or total product cost | Hourly rates, fixed fee, or not-to-exceed |

Quality Control | Physical inspection, testing | Performance review, deliverable acceptance |

Matching | 3-way match (PO-GRN-Invoice) | 2-way or milestone-based matching |

Service PO Structure:

Scope of Work Section:

Detailed description of services to be performed

Expected outcomes and deliverables

Timeline and milestones

Performance standards and metrics

Dependencies and assumptions

Resource Allocation:

Specific individuals or skill levels required

On-site vs. remote work specifications

Equipment or tools to be provided

Workspace or access requirements

Deliverables and Acceptance:

Tangible outputs expected

Format and delivery method

Review and approval process

Acceptance criteria

Revision or correction process

Service Level Agreements (SLAs):

Response time requirements

Availability commitments

Quality standards

Escalation procedures

Remedies for non-performance

Examples of Service POs:

Consulting Services:

Service: Market Research and Strategy Development

Provider: Strategic Insights LLC

Duration: 8 weeks (Nov 1 - Dec 31, 2025)

Deliverables:

- Week 2: Industry analysis report

- Week 4: Competitive landscape assessment

- Week 6: Customer survey results and analysis

- Week 8: Strategic recommendations presentation

Rate: $250/hour for senior consultant, $150/hour for analyst

Not-to-exceed: $45,000

Payment: Net 30 upon milestone completion and approval

Maintenance Services:

Service: Quarterly HVAC Maintenance

Provider: Climate Control Services

Coverage: 5 locations, 24 units

Schedule: January, April, July, October 2025

Scope:

- Filter replacement

- System inspection and testing

- Preventive maintenance per manufacturer specs

- Emergency service (4-hour response) included

Pricing: $8,500 per quarter ($34,000 annual)

Payment: Invoiced quarterly in arrears

Software/IT Services:

Service: Cloud Infrastructure Management

Provider: CloudOps Partners

Term: 12 months (Nov 1, 2025 - Oct 31, 2026)

Services Included:

- 24/7 monitoring and alerting

- Patch management and updates

- Monthly optimization reviews

- Quarterly capacity planning

- Unlimited support tickets

SLA: 99.9% uptime, 15-minute response to critical issues

Monthly Fee: $12,000

Annual Total: $144,000

Payment: Monthly in advance via ACH

Service PO Approval Considerations:

Service purchases often warrant different approval flows:

Scope Validation: Does the service align with business needs?

Resource Verification: Are internal resources unavailable or insufficient?

Budget Impact: Does the cost justify the value delivered?

Vendor Capability: Does the supplier have proven expertise?

Risk Assessment: What are the consequences of poor performance?

Organizations implementing intelligent approval workflows route service POs to appropriate subject matter experts, not just financial approvers.

Supplier-Specific POs

Different suppliers require tailored approaches based on relationship type, business volume, and contractual arrangements. Managing supplier-specific purchase orders optimizes both efficiency and relationship quality.

Strategic Suppliers:

High-volume, long-term relationships characterized by:

Master Service Agreements (MSAs): Overarching terms governing all transactions

Blanket POs: Streamlined releases against pre-negotiated terms

Preferred Pricing: Volume discounts and special rates

Integration: EDI or API connections for automated ordering

Collaborative Planning: Demand forecasts and capacity planning

Example: A manufacturer with a critical component supplier issues a $2M annual blanket PO with quarterly reviews, automated release triggers based on inventory levels, and integrated delivery scheduling.

Tactical Suppliers:

Regular but not strategic relationships:

Standard Terms: Negotiated terms for common purchases

Simplified Approval: Pre-approved for specific categories

Moderate Documentation: Standard PO templates

Performance Monitoring: Basic delivery and quality tracking

Spot Suppliers:

One-time or infrequent purchases:

Full Documentation: Complete PO with all terms specified

Enhanced Due Diligence: Verification of capability and credentials

Standard Payment Terms: No special arrangements

Higher Approval Thresholds: Additional scrutiny for new vendors

Managing Supplier Variations:

Custom Terms Handling:

Different suppliers may require unique terms:

Payment Terms: Some offer discounts for early payment, others require deposits

Shipping: Freight terms vary by supplier size and location

Returns: Restocking fees, RMA processes, warranty periods

Minimums: Order minimums or lot sizes

Lead Times: Production and delivery schedules

Organizations should maintain supplier profiles in their ERP or vendor management system that automatically populate POs with supplier-specific terms.

Delivery Milestone Management:

Complex purchases may require phased delivery:

Construction Project Example:

PO Total: $450,000 - Commercial HVAC Installation

Milestone 1 (Week 2): Design and Engineering - $50,000

Milestone 2 (Week 6): Equipment Procurement - $200,000

Milestone 3 (Week 10): Installation Phase 1 - $100,000

Milestone 4 (Week 14): Installation Phase 2 - $100,000

Payment: Net 15 after milestone completion and inspection

Retention: 10% held until final acceptance

Software Implementation Example:

PO Total: $180,000 - ERP Implementation Services

Phase 1: Discovery and Design (Weeks 1-4) - $40,000

Phase 2: Configuration and Development (Weeks 5-12) - $70,000

Phase 3: Testing and Training (Weeks 13-16) - $40,000

Phase 4: Go-Live Support (Weeks 17-20) - $30,000

Payment: Upon phase acceptance

Warranty: 90 days post-implementation support included

Tracking Purchase Orders across multiple milestones requires robust PO tracking systems that monitor both financial and operational progress.

Supplier Relationship Considerations:

Strong supplier relationships benefit from:

Clear Communication: Unambiguous PO terms and expectations

Timely Payment: Adherence to payment terms builds trust

Performance Feedback: Regular reviews and constructive dialogue

Issue Resolution: Fair and prompt handling of problems

Growth Opportunities: Increasing business for good performers

Vendor relationship management extends beyond transactions to strategic partnership development, and purchase orders serve as the tactical execution mechanism for these relationships.

Purchase Order Best Practices

Process Efficiency

Efficient purchase order processes directly impact procurement cycle times, working capital management, and overall organizational agility. Leading practices focus on automation, standardization, and continuous improvement.

Centralized PO Tracking:

Organizations should maintain a single source of truth for all purchase orders:

Key Tracking Metrics:

Metric | Definition | Target |

PO Creation Time | Hours from requisition to issued PO | < 24 hours |

Approval Cycle Time | Hours in approval workflow | < 4 hours |

Supplier Acknowledgment Rate | % of POs acknowledged within 48 hours | > 95% |

On-Time Delivery | % delivered by required date | > 90% |

Perfect Order Rate | % with no receiving or invoice issues | > 85% |

PO Closure Time | Days from receipt to PO closure | < 7 days |

Automated PO tracking systems provide real-time visibility into these metrics, enabling proactive management of exceptions and bottlenecks.

Version Control:

Purchase orders may require modifications after issuance:

Change Orders: Formal amendments to original PO

Version Numbering: PO-2025-1234 Rev 1, Rev 2, etc.

Audit Trail: Complete history of what changed, when, and by whom

Supplier Notification: Automatic alerting of changes

Historical Access: Ability to view previous versions

Modern systems maintain immutable logs of all PO changes, ensuring audit compliance and eliminating confusion about which version is current.

Automation Opportunities:

Pre-Approval Automation:

Budget availability checks before PO creation

Policy compliance validation

Duplicate PO detection

Preferred supplier recommendations

Approval Routing:

Rule-based routing by amount, category, department

Parallel approvals for faster processing

Mobile approval capabilities

Automatic escalation for aged approvals

PO Generation:

Auto-populate from requisitions

Supplier master data integration

Standard terms application

Tax calculation automation

Post-Issuance:

Automatic supplier notification

Acknowledgment tracking and follow-up

Delivery status monitoring

Exception alerting

Organizations implementing end-to-end PO automation report 60-80% reduction in cycle times and 95%+ reduction in manual data entry.

Reducing Manual Handoffs:

Each handoff in the PO process introduces delay and error risk:

Traditional Process:

Requestor emails need to procurement (handoff)

Procurement creates requisition (handoff)

Manager approves via email (handoff)

Procurement creates PO manually (handoff)

Procurement emails PO to supplier (handoff)

Supplier emails acknowledgment (handoff)

Automated Process:

Requestor submits via self-service portal

System routes for approval based on rules

Auto-generates PO upon approval

Electronically transmits to supplier

Captures acknowledgment in system

From six handoffs to zero, with complete digital workflow.

Compliance and Recordkeeping

Purchase orders create legal obligations and financial commitments that must be properly documented, controlled, and retained.

Audit Trail Requirements:

Every PO should have a complete digital trail documenting:

Pre-Approval:

Who requested the purchase and when

Business justification provided

Budget authorization reference

Alternative options considered

Approval:

Who approved and at what level

Timestamp of each approval

Any conditions or notes attached

Policy rules applied

Issuance:

When PO was issued to supplier

Transmission method and confirmation

Supplier acknowledgment received

Any negotiations or changes

Execution:

Delivery dates and receiving records

Quality inspection results

Invoice receipt and matching

Payment execution and date

Closure:

Final reconciliation

Warranty or service period tracking

Close-out approval

Archival location

Accounts payable document management systems maintain these comprehensive records while ensuring proper access controls and retention policies.

Internal Controls:

Effective PO processes incorporate segregation of duties:

Function | Responsible Party | Never Same As |

Requisition | Department/Requester | Approver, Receiver |

Approval | Manager/Budget Owner | Requisitioner, PO Creator |

PO Creation | Procurement | Approver, Receiver |

Receiving | Warehouse/Dept | Requisitioner, AP |

Invoice Processing | Accounts Payable | Requisitioner, Receiver |

Payment | Treasury/AP | All above |

This separation prevents fraud and ensures proper checks and balances.

Policy Compliance:

Organizations should maintain documented purchasing policies covering:

Authority Limits: Who can approve what dollar amounts

Supplier Selection: Competitive bidding requirements, preferred vendors

Approval Requirements: When multiple approvals are needed

Documentation Standards: Required supporting documents

Exceptions Process: How to handle policy variances

AI-powered policy checking can automatically flag POs that violate policy rules, preventing non-compliant purchases before they occur.

Data Accuracy:

Inaccurate data creates operational problems and compliance risks:

Common Data Quality Issues:

Incorrect supplier information (wrong address, contact, terms)

Missing or wrong GL codes (misallocated expenses)

Tax calculation errors (over/underpayment, compliance issues)

Incomplete item descriptions (receiving confusion, wrong items)

Price discrepancies (budget impact, matching failures)

Data Quality Controls:

Master data governance for suppliers and items

Validation rules preventing incomplete submissions

Duplicate detection algorithms

Standardized formats and dropdown lists

Regular data quality audits

Organizations with strong data governance achieve 99%+ PO accuracy, virtually eliminating downstream processing issues.

Retention and Archival:

Purchase orders must be retained per regulatory and business requirements:

Typical Retention Periods:

Tax Purposes: 7 years (IRS requirement)

Legal: Per statute of limitations (varies by jurisdiction)

Warranty: Duration of warranty period

Contracts: Per contract term plus 7 years

Audit: Per audit schedule and requirements

Archival Best Practices:

Digital archival in searchable, indexed systems

Offsite backup with disaster recovery

Access controls ensuring only authorized retrieval

Immutable records preventing post-facto alterations

Regular testing of archival integrity

Cloud-based systems offer advantages for long-term retention, with geographic redundancy and automatic backup.

Template Management and Customization

Organizations evolve, and purchase order templates must evolve with them. Effective template management balances standardization with flexibility.

Template Governance:

Ownership and Maintenance:

Procurement owns template standards

Finance reviews for compliance and controls

Legal reviews terms and conditions

IT ensures technical compatibility

Department heads provide functional input

Review Cadence:

Annual comprehensive review

Quarterly update for regulatory changes

Ad hoc updates for business changes

Version control and change documentation

Template Library Structure:

By Transaction Type:

Standard goods purchase

Services and consulting

Construction and capital projects

Software and technology

Travel and entertainment

Blanket and standing orders

By Department:

Department-specific fields and approvals

Tailored terms and conditions

Custom GL code structures

Unique compliance requirements

By Approval Level:

Simplified templates for low-value purchases

Enhanced documentation for high-value orders

Executive-level approval formats

Emergency purchase procedures

Customization Guidelines:

When to Customize:

Unique legal requirements

Specialized supplier relationships

Complex project structures

Multi-phase deliverables

International transactions

When to Standardize:

Routine, repetitive purchases

Established supplier relationships

Standard goods and services

Low-value transactions

High-volume categories

Balancing Act:

Too much customization creates:

Training complexity

Processing delays

Quality control challenges

System maintenance burden

Too little customization creates:

Inadequate documentation

Compliance gaps

Supplier confusion

Operational inefficiencies

Leading organizations maintain 5-10 core templates covering 90%+ of transactions, with custom templates requiring special approval.

Common Challenges and How to Overcome Them

Manual Errors and Delays

Despite best intentions, manual purchase order processes suffer from predictable problems that automation effectively solves.

Typical Manual Errors:

Data Entry Mistakes:

Transposed numbers in pricing or quantities

Incorrect supplier information

Wrong GL codes or cost centers

Miscalculated taxes or totals

Typos in item descriptions

Impact: Receiving errors, invoice matching failures, budget misallocation, payment delays, supplier frustration

Missing Information:

Incomplete delivery addresses

Missing required approval signatures

Omitted tax exemption certificates

Unclear payment terms

Absent delivery dates

Impact: Delivery problems, processing holds, compliance issues, supplier confusion

Duplicate POs:

Same request processed multiple times

Manual and system POs for same purchase

Multiple team members creating POs independently

Impact: Double deliveries, overspending, payment disputes, inventory issues

Version Confusion:

Multiple PO drafts in circulation

Outdated templates used

Changes not communicated

Supplier working from wrong version

Impact: Wrong items delivered, pricing disputes, contract disagreements

Process Delays:

Manual processes introduce delays at every step:

Approval Bottlenecks:

Approvers on vacation or unavailable

Email approvals lost or overlooked

Unclear routing or authorization levels

Multiple sequential approvals required

Manual Data Entry:

Retyping information from requisitions

Looking up supplier details manually

Calculating totals and taxes by hand

Formatting and printing POs

Physical Routing:

Paper documents circulated for signatures

Faxing or mailing POs to suppliers

Filing and archiving physical copies

Follow-up Activities:

Manual tracking of acknowledgments

Checking delivery status individually

Reconciling POs to receipts and invoices

Solutions:

Purchase order automation platforms address these challenges through:

Automated Data Validation:

Required field enforcement

Format checking (dates, phone numbers, emails)

Mathematical validation

Duplicate detection

Master data lookup and verification

Intelligent Workflows:

Rule-based approval routing

Parallel approvals when appropriate

Mobile approval capabilities

Automatic escalation

Real-time status visibility

Electronic Document Management:

Digital storage and retrieval

Version control

Audit trail capture

Secure access controls

Searchable archive

Integration:

Direct ERP connectivity

Supplier portal access

Email and notification automation

Electronic acknowledgment capture

Organizations implementing these solutions report 75-90% reduction in errors and 60-80% reduction in cycle times.

Lost Visibility Across Teams

Purchase orders touch multiple departments, and without centralized visibility, coordination suffers.

Common Visibility Gaps:

Procurement's Perspective:

What has been requested but not yet approved?

Which POs are awaiting supplier acknowledgment?

Where are delivery delays occurring?

What spend is committed but not yet received?

Finance's Perspective:

What commitments exist against budgets?

Which invoices should we expect and when?

Are there unmatched invoices or receipts?

What accruals need to be recorded?

Department's Perspective:

What is the status of my requisition?

When will my order arrive?

Why hasn't my PO been approved?

Where is the item I ordered weeks ago?

Receiving's Perspective:

What deliveries are expected today/this week?

Which POs should these receipts be matched to?

Who should I contact about discrepancies?

Where should different items be delivered?

Solutions for Visibility:

Centralized PO Management Platform:

A single system of record that provides:

Real-time Status: Where every PO is in the workflow

Role-Based Dashboards: Relevant view for each stakeholder

Search and Filter: Find specific POs instantly

Notifications: Proactive alerts for exceptions

Reporting: Analytics and trend analysis

Self-Service Portals:

Empower stakeholders to check status without contacting procurement:

Requestors track requisition and PO status

Departments view spending against budgets

Suppliers access PO details and update delivery information

Finance sees committed vs. actual spending

Automated Status Updates:

Eliminate manual status requests through:

Automatic email notifications at key milestones

Mobile app push notifications

Integration with collaboration tools (Slack, Teams)

Scheduled status reports

Exception-Based Management:

Rather than tracking everything manually, focus on exceptions:

POs awaiting approval beyond SLA

Overdue supplier acknowledgments

Late deliveries

Receiving discrepancies

Invoice matching failures

SLA and exception management tools automatically surface issues requiring attention, allowing teams to manage by exception rather than constant monitoring.

Solutions and Tools

The purchase order management landscape includes diverse technology solutions, from basic spreadsheets to advanced AI-powered platforms.

Solution Categories:

1. Manual/Spreadsheet-Based:

Pros:

No software cost

Familiar to all users

Completely customizable

No implementation required

Cons:

High error rates

No workflow automation

Limited scalability

Version control challenges

No integration capabilities

Appropriate for: Micro businesses with very low transaction volumes (< 20 POs/month)

2. Accounting Software:

Examples: QuickBooks, Xero, FreshBooks, Sage

Pros:

Integrated with financial system

Basic approval workflows

Standard reporting

Moderate cost

Familiar interface

Cons:

Limited customization

Basic procurement features

May lack advanced approval routing

Limited supplier collaboration

Appropriate for: Small businesses with straightforward requirements (20-200 POs/month)

3. ERP Systems:

Examples: SAP, Oracle NetSuite, Microsoft Dynamics, Sage Intacct, Epicor

Pros:

Comprehensive P2P integration

Multi-entity and multi-currency

Advanced controls and compliance

Extensive reporting and analytics

Mature, proven systems

Cons:

High implementation cost and time

Complexity requires training

May require customization

User experience can be dated

Change management required

Appropriate for: Mid-market to enterprise organizations with complex requirements

Leading ERP platforms like NetSuite, Microsoft Dynamics, and SAP provide robust PO management, but often benefit from supplementary AI automation layers.

4. Specialized Procurement Platforms:

Examples: Coupa, SAP Ariba, Procurify, Ivalua

Pros:

Purpose-built for procurement

Supplier collaboration portals

Advanced sourcing and analytics

Spend visibility and control

Modern user experience

Cons:

Requires integration with ERP/accounting

Significant implementation effort

May duplicate some ERP functionality

Ongoing license costs

Appropriate for: Organizations prioritizing procurement excellence and supplier collaboration

5. AI-Powered Automation:

Examples: Hyperbots, emerging AI-first platforms

Pros:

Intelligent document processing

Natural language interactions

Continuous learning and improvement

Rapid deployment

Enhances existing systems rather than replacing

Cons:

Newer technology category

Requires change management

AI accuracy requires monitoring

Appropriate for: Organizations seeking breakthrough efficiency gains without ERP replacement

Hyperbots' Procurement Co-Pilot exemplifies this category, providing:

Conversational requisition intake

Intelligent PO generation

Smart approval routing

Automated supplier communication

Exception detection and resolution

Continuous process optimization

Selection Criteria:

When evaluating PO management solutions, consider:

1. Transaction Volume:

How many POs do you create monthly?

What is your growth trajectory?

Are there seasonal spikes?

2. Complexity:

Single vs. multi-entity

Domestic vs. international

Simple vs. complex approval chains

Standard vs. customized requirements

3. Integration Needs:

What systems must the PO system connect to?

Are APIs available?

Is real-time vs. batch integration required?

4. User Experience:

Who will use the system and how frequently?

What is their technical sophistication?

Mobile access requirements?

5. Budget:

Upfront vs. subscription costs

Implementation and training expenses

Ongoing maintenance and support

ROI timeline expectations

6. Vendor Stability:

Financial health and customer base

Product roadmap and innovation

Support quality and responsiveness

Industry expertise

Organizations increasingly adopt a "best-of-breed" approach, combining ERP core functionality with specialized tools like automated invoice processing, payment optimization, and accruals management that integrate with existing systems.

Conclusion

Purchase orders represent far more than administrative paperwork, they're the foundation of transparent, controlled, and efficient procurement operations. Organizations that master PO management gain competitive advantages through faster cycle times, better supplier relationships, tighter budget controls, and audit-ready documentation.

Key Takeaways:

1. Foundation Matters: Understanding what purchase orders are, their legal significance, and how they differ from requisitions and invoices is essential for everyone involved in procurement and finance.

2. Process Excellence: The complete PO lifecycle, from requisition through payment must be well-defined, consistently followed, and continuously improved. Each step adds value through authorization, documentation, and control.

3. Templates and Standards: Standardized PO templates and document formats ensure consistency, reduce errors, and accelerate processing. Organizations should maintain template libraries tailored to different transaction types while avoiding excessive customization.

4. Specialized Approaches: Different purchasing scenarios standard goods vs. services, strategic vs. spot suppliers, require adapted PO structures and approval logic.

5. Automation Imperative: Manual PO processes simply cannot deliver the speed, accuracy, and visibility modern businesses require. Purchase order automation has evolved from basic workflow tools to intelligent, AI-powered systems that learn, adapt, and optimize continuously.

6. Integration and Visibility: Purchase orders must integrate seamlessly with requisitioning, receiving, invoice processing, and payment systems. End-to-end P2P automation eliminates silos and provides real-time visibility across the procurement lifecycle.

7. Compliance and Controls: Proper PO processes enforce segregation of duties, maintain audit trails, ensure policy compliance, and create the documentation necessary for internal and external audits.

Next Steps:

Organizations looking to improve their purchase order processes should:

Assess Current State: Document existing processes, identify pain points, measure key metrics

Define Future State: Establish goals for cycle time, accuracy, visibility, and compliance

Select Appropriate Tools: Match solution sophistication to organizational needs and budget

Implement Systematically: Phase rollout by department, transaction type, or volume

Train and Support: Ensure all stakeholders understand new processes and tools

Measure and Optimize: Track metrics, gather feedback, continuously refine

Explore Further:

This pillar guide provides comprehensive coverage of purchase order fundamentals, but many topics deserve deeper exploration:

For organizations ready to transform their procurement operations, Hyperbots' AI-powered solutions offer:

Intelligent requisition intake and PO generation

Automated approval routing and exception handling

Supplier communication and collaboration

Three-way matching and invoice processing

Payment optimization and cash management

Continuous learning and process improvement

The future of purchase order management lies not in incremental improvements to manual processes, but in fundamentally reimagining procurement through artificial intelligence that handles routine transactions flawlessly while elevating human expertise to focus on strategy, relationships, and value creation.

Organizations that embrace this transformation today will lead their industries tomorrow - with faster operations, better controls, stronger supplier partnerships, and finance teams freed to focus on insight and strategy rather than transaction processing.

Start your purchase order transformation journey today by exploring the detailed guides linked throughout this resource and evaluating how modern automation can revolutionize your procurement operations.

Frequently Asked Questions (FAQs)

Q: What's the difference between a purchase order and an invoice?

A: A purchase order is created by the buyer before goods or services are delivered, authorizing the purchase. An invoice is created by the seller after delivery, requesting payment. The PO creates the obligation; the invoice fulfills it. Understanding this distinction is crucial for proper invoice processing and three-way matching.

Q: Do I need a purchase order for every purchase?

A: Not necessarily. Organizations typically set dollar thresholds below which POs aren't required (e.g., purchases under $500). However, even small purchases benefit from PO discipline for budget tracking and audit trails. Best practices for PO approvals help determine when POs add value versus administrative burden.

Q: How long should I retain purchase orders?

A: Generally, retain POs for at least 7 years to satisfy tax and audit requirements. Certain industries or contract types may require longer retention. Digital archival in accounts payable document management systems makes long-term retention practical and cost-effective.

Q: Can I modify a purchase order after it's been issued?

A: Yes, but with proper controls. Issue a change order or amended PO, maintain version control, notify the supplier formally, and document the reason for changes. Never modify the original without creating an audit trail. Modern PO management systems automatically track revisions and maintain complete history.

Q: What is three-way matching and why does it matter?

A: Three-way matching compares the purchase order, goods receipt, and supplier invoice to ensure they align before approving payment. This prevents overpayment, catches errors, and detects potential fraud. AI-powered matching solutions achieve 95%+ automation rates, dramatically reducing manual effort.

Q: How can I speed up PO approval cycles?

A: Implement automated approval workflows with rule-based routing, enable mobile approvals, use parallel approvals when appropriate, set up automatic escalation for aged approvals, and eliminate unnecessary approval layers. Organizations using intelligent PO approval software reduce approval times from days to hours or minutes.

Q: What's the best way to handle emergency purchases?

A: Establish a documented emergency purchase procedure with: (1) clear definition of what qualifies as an emergency, (2) designated emergency approvers available 24/7, (3) simplified PO process with abbreviated approval chain, (4) requirement for follow-up documentation, and (5) periodic review to prevent abuse. Even emergencies benefit from streamlined PO creation processes.

Q: Should purchase orders for services differ from product POs?

A: Yes. Service POs require different elements including scope of work, deliverables, acceptance criteria, hourly rates or milestone payments, and service level agreements. The approval logic often differs too, with emphasis on scope validation rather than just price.

Q: How do I prevent duplicate purchase orders?

A: Implement duplicate detection algorithms that check for matching supplier, amount, and line items. Centralize PO creation in procurement rather than allowing multiple departments to create POs independently. Use automated PO systems that flag potential duplicates before issuance.

Q: What information is legally required on a purchase order?

A: At minimum: unique PO number, buyer and seller legal names and addresses, PO date, itemized description of goods/services, quantities, prices, total amount, delivery terms, and payment terms. Additional requirements vary by jurisdiction and industry. Consult legal counsel for specific compliance needs.

Q: How can AI improve purchase order processes?

A: AI enhances PO processes through intelligent document extraction, automated data validation, smart approval routing, anomaly detection, spend pattern analysis, and continuous learning. AI-powered procurement solutions achieve 80%+ efficiency gains while improving accuracy and compliance.

Q: What's a blanket purchase order and when should I use one?

A: A blanket PO establishes terms for multiple purchases over time, typically with a maximum dollar amount and validity period. Use blanket POs for regularly purchased items with predictable ongoing needs, like office supplies, maintenance services, or standard components. They reduce administrative overhead while maintaining spending controls.

Q: How do I handle purchase orders in multiple currencies?

A: Specify the currency clearly on the PO, use exchange rates from your financial system or a standard source, consider exchange rate hedging for large amounts, and document the exchange rate methodology. Modern ERP systems handle multi-currency transactions automatically with built-in exchange rate management.

Q: What reports should I generate from my PO system?

A: Key reports include: open POs by department/supplier/age, committed vs. actual spending, PO approval cycle time, supplier acknowledgment rates, on-time delivery performance, invoice matching exceptions, and PO-to-payment cycle time. Comprehensive PO tracking enables these critical analytics.

Q: Should I use an online purchase order system?

A: Cloud-based systems offer significant advantages: anywhere/anytime access, automatic updates and backups, scalability without infrastructure investment, lower upfront costs, and easier integration. The question isn't whether to go online, but which online PO system best fits your needs.

The Future of Purchase Order Management

The purchase order landscape continues evolving rapidly, driven by technological innovation and changing business needs:

Emerging Trends:

1. Artificial Intelligence and Machine Learning: Beyond today's automation, AI will increasingly:

Predict optimal order quantities and timing

Recommend suppliers based on performance and risk

Identify savings opportunities automatically

Detect fraud and anomalies in real-time

Negotiate terms on behalf of procurement

Agentic AI in finance and procurement represents the next frontier, with autonomous agents handling routine decisions while escalating exceptions to humans.

2. Blockchain and Smart Contracts: Distributed ledger technology enables:

Immutable PO records and audit trails

Automated execution of contract terms

Real-time payment upon delivery confirmation

Enhanced transparency across supply chains

Reduced dispute resolution time

3. Internet of Things (IoT) Integration: Connected devices will:

Trigger automatic reordering based on inventory sensors

Provide real-time delivery tracking

Confirm receipt automatically via RFID

Monitor quality conditions during transit

Update PO status without human intervention

4. Conversational Commerce: Natural language interfaces will enable:

Voice-activated requisition and PO creation

Chatbot-driven supplier communication

Question-answering about PO status

Verbal approval workflows

Hands-free procurement operations

5. Sustainability and ESG Integration: Purchase orders will increasingly incorporate:

Carbon footprint tracking

Supplier diversity metrics

Ethical sourcing certifications

Circular economy provisions

ESG scoring and reporting

6. Hyper-Automation: The convergence of AI, RPA, and workflow automation will:

Achieve 95%+ straight-through processing

Eliminate manual data entry completely

Enable touchless procurement cycles

Reduce PO-to-payment from weeks to hours

Free procurement teams for strategic work

Preparing for the Future:

Organizations should position themselves for these advances by:

Building Digital Foundations: Move from paper and email to digital PO systems

Investing in Data Quality: Clean, standardized master data is prerequisite for AI

Embracing Cloud Platforms: Cloud-based systems receive continuous innovation

Cultivating Change Readiness: Prepare teams for rapidly evolving processes

Partnering with Innovators: Work with vendors pushing technological boundaries

The future of purchase order management isn't about incremental improvements, it's about fundamental transformation. Organizations that embrace this change will gain dramatic competitive advantages in speed, cost, and strategic capability.

Transform Your Procurement:

Ready to revolutionize your purchase order processes? Explore how Hyperbots' AI-powered co-pilots can help you:

✓ Reduce PO cycle time by 80% through intelligent automation

✓ Achieve 99%+ accuracy in PO creation and matching

✓ Free your team from manual work to focus on strategic value

✓ Gain real-time visibility across the entire procurement lifecycle

✓ Ensure compliance with automated policy enforcement

✓ Optimize spending through AI-powered insights and recommendations

Whether you're creating your first purchase order or managing thousands monthly, the principles remain the same: clarity, control, consistency, and continuous improvement. Apply the practices outlined in this guide, leverage the resources provided, and embrace technology that amplifies human expertise.

The future of purchase order management is intelligent, automated, and strategic. Your journey toward that future starts now.